Korantada warshaduhu waa daawaynta dusha sare ee si weyn loo isticmaalo si loo ilaaliyobiraha shubiddaiyo CNC machining alaabta ka daxalka leh dhammayn wanaagsan. Macaamiil badan ayaa weydiiya su'aalo ku saabsan daaweynta dusha sare ee biraha tuurista iyoqaybaha mashiinada saxda ah. Maqaalkani waxa uu diiradda saari doonaa habka daahan electrophoretic. Waxaan rajeynayaa inay waxtar u yeelan doonto dhammaan lammaanayaasha.

Electrocoating waa habka daahan kaas oo qayb ka mid ah midabada iyo resins ku xayiran xal electrophoretic ay u jihaysan yihiin inay u haajiraan oo ay ku shubaan dusha mid ka mid ah electrodes iyadoo la isticmaalayo beer koronto dibadda ah. Mabda'a daahan electrophoretic ayaa la abuuray dhamaadkii 1930-meeyadii, laakiin tignoolajiyadan ayaa la sameeyay oo la helay codsi warshadeed ka dib 1963. Daahan Electrophoretic waa habka ugu waxtarka badan ee dhismaha ee ku salaysan biyaha. Dahaarka Electrophoretic wuxuu leeyahay sifooyinka milanka biyaha, aan sunta ahayn, iyo xakamaynta tooska ah ee fudud. Sababtoo ah waa ku haboon tahay daaweynta dusha sare ee workpieces conductive (kabka biraha, qaybo mishiin, forgings, sheet biraha qaybo alxanka, iwm), habka daahan electrophoretic ayaa si degdeg ah loo isticmaalo in warshadaha sida baabuurta, qalabka dhismaha, hardware , iyo qalabka guriga.

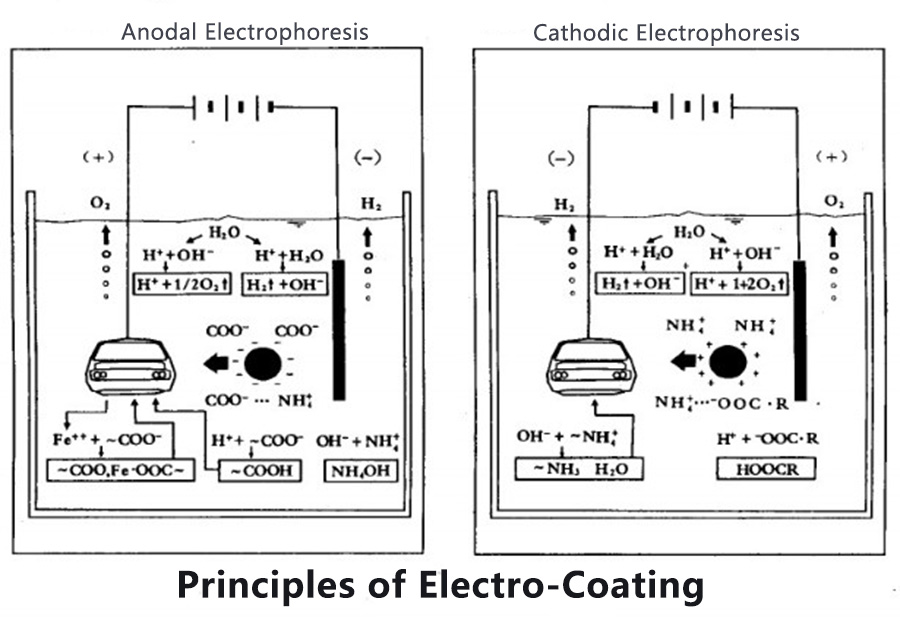

Mabaadi'da

Resin-ka ku jira dahaarka electrophoretic ee cathodic wuxuu leeyahay kooxo asaasi ah, kuwaas oo sameeya milix ka dib dhexdhexaadinta aashitada oo ku milmi biyaha. Ka dib markii hadda si toos ah loo codsado, ion acid radical negative u dhaqaaqo anode ah, iyo resin ions iyo qaybaha midabka iyaga ku duudduubay u guuraan cathode oo leh lacag wanaagsan oo lagu shubaa on cathode ah. Tani waa mabda'a aasaasiga ah ee daahan electrophoretic (badanaa loo yaqaan plating). Dahaarka Electrophoresis waa fal-celin koronto oo aad u adag, ugu yaraan afar saameyn ee electrophoresis, electrodeposition, electrolysis, iyo electroosmosis isku mar dhacaan.

Electrophoresis

Ka dib markii anode iyo cathode ee xalka kolloidal ay ku shaqeeyaan, qaybaha kolloidal waxay u guuraan dhinaca cathode (ama anode) oo hoos yimaada ficilka beerta korontada, oo loo yaqaan 'electrophoresis'. Walaxda ku jirta xalinta kolloidal kuma jirto xaaladda molecules iyo ions, laakiin solute-ka ayaa ku kala firirsan dareeraha. Walaxda waa weyn tahay oo kuma soo degi doonto xaalad kala firirsan.

Electrodeposition

Dhacdada roobabka adag ee dareeraha ah waxaa loo yaqaan agglomeration (agglomeration, deposition), taas oo guud ahaan la soo saaro marka la qaboojiyo ama la saaro xalka, iyo daahan electrophoretic waxay ku tiirsan tahay koronto. Dahaarka elektiroonigga ee cathodic, walxaha si togan loo dallacay ayaa wadar ahaan ku urura cathode-ka, iyo qaybo si xun u dallacay (ie ions) wadar ahaan anode-ka. Marka qaybaha kolloidal ee si togan loo soo oogay (resin iyo pigment) ay gaadhaan cathode (substrate) Ka dib aagga dusha sare (lakabka aadka u sarreeya ee alkaline), elektaroonnada ayaa la helaa oo ay la falgalaan ions hydroxide si ay u noqdaan walxo biyo-la'aan ah, kuwaas oo lagu shubo cathode ( workpiece rinji).

Electrolysis

Xalka leh conductivity ionic, anode iyo cathode waxay ku xiran yihiin si toos ah hadda, anions ayaa soo jiidanaya anode, iyo cations ayaa soo jiidanaya cathode, falcelin kiimikaad ayaa dhacaya. Anode-ku waxa uu soo saaraa kala dirida birta iyo oxidation electrolytic si uu u soo saaro ogsijiin, chlorine, iwm. Birtu waxay ku soo degdegtaa cathode-ka H+-na si elektrolytically ah ayaa loo dhimay hydrogen.

Electroosmosis

Ka dib labada daraf (cathode iyo anode) ee xalalka kala duwan ee kala duwan oo ay kala soocaan xuubka semipermeable ayaa la tamar-geliyay, ifafaale in xalka-fiirsashada hoose uu u guuro dhinaca sare ee xoojinta waxaa loo yaqaan 'electroosmosis'. Filimka dahaarka ah ee kaliya ee lagu dhejiyay dusha sare ee shayga la daboolay waa filim semi-permeable ah. Marka la eego ficilka joogtada ah ee beerta korantada, biyaha ku jira sifeynta filimka smearing ayaa ka soo baxa filimka waxayna u guuraan qubeyska si ay u fuuq baxaan filimka. Tani waa electroosmosis. Electroosmosis wuxuu u rogaa filimka daahan hydrophilic filim daahan hydrophobic, iyo fuuqbaxa ka dhigaysa daahan filimka cufan. Rinjiga qoyan ka dib dabaasha oo leh rinji elektrophoretic ah oo wanaagsan waa la taaban karaa oo aan dhegdheg lahayn. Waxaad ku raaci kartaa dareeraha qubayska ee ku dheggan filimka rinjiga qoyan biyo.

Astaamaha Electrocoating

Filimka rinjiga Electrophoretic wuxuu leeyahay faa'iidooyinka buuxa, lebbiska, fidsanaanta iyo dahaarka siman. Adkeysiga, adhesion, caabbinta daxalka, waxqabadka saamaynta, iyo permeability ee filimka rinjiga electrophoretic ayaa aad uga fiican hababka kale ee daahan.

(1) Rinjiga biyaha ku milma ayaa loo isticmaalaa, biyaha waxaa loo isticmaalaa sida dhexdhexaadinta, taas oo badbaadisa wax badan oo dareere organic ah, si weyn u yareynaya wasakhowga hawada iyo khataraha deegaanka, waa badbaado iyo nadaafad, kana fogaada khatarta qarsoon ee dabka;

(2) Waxtarka rinjiyeynta ayaa sarreeya, luminta rinjiga waa yar yahay, iyo heerka isticmaalka rinjiga wuxuu gaari karaa 90% ilaa 95%;

(3) Dhumucda filimka dahaarka waa lebis, adhesion waa xoog badan yahay, tayada daahan ayaa wanaagsan. Qayb kasta oo ka mid ah workpiece-ka, sida lakabka gudaha, niyad-jabka, alxanka, iwm, waxay heli karaan filim daahan labis ah oo siman, kaas oo xalliya dhibaatada hababka kale ee daahan ee workpieces-qaabeeya adag. Dhibaatada rinjiyeynta;

(4) Wax-soo-saarka wax-soo-saarku waa mid sarreeya, dhismuhuna wuxuu xaqiijin karaa wax-soo-saarka tooska ah iyo joogtada ah, kaas oo si weyn u wanaajinaya waxtarka shaqada;

(5) Qalabku waa adag yahay, kharashka maalgashigu waa sarreeyaa, isticmaalka korantadu waa weyn yahay, heerkulka loo baahan yahay qalajinta iyo daawaynta ayaa sarreeya, maaraynta rinjiga iyo rinjiyeynta waa adag tahay, shuruudaha dhismuhu waa adag yihiin, iyo daaweynta biyaha wasakhda ah ayaa loo baahan yahay. ;

(6) Kaliya rinjiga biyaha ku milma ayaa la isticmaali karaa, midabkana lama bedeli karo inta lagu jiro habka daahan. Xasiloonida rinjiga ma fududa in la xakameeyo ka dib kaydinta muddo dheer.

(7) Qalabka dahaarka ee electrophoretic waa mid adag oo tiknoolajiyadu waa mid sarreeya, taas oo ku habboon soo saarista midab go'an.

Xaddidaadaha Electrocoating

(1) Waxay ku habboon tahay oo kaliya daahanka asaasiga ah ee substrate-ka korantada sida qaybaha mishiinada ee biraha birta ah iyo biraha aan birta ahayn. Waxyaabaha aan shaqaynayn sida alwaax, caag, maro, iwm laguma dahaadhi karo habkan.

(2) Habka daahan Electrophoretic kuma haboona walxaha dahaarka ah ee ka kooban biraha badan, haddii sifooyinka electrophoresis ka duwan yihiin.

(3) Habka dahaarka Electrophoretic looma isticmaali karo walxaha dahaarka leh ee aan u adkeysan karin heerkulka sare.

(4) Daahan Electrophoretic kuma habboona dahaarka leh shuruudaha xaddidan ee midabka. Dahaarka Electrophoretic ee midabyo kala duwan ayaa u baahan in lagu rinjiyeeyo meelo kala duwan.

(5) daahan Electrophoretic laguma talinayo wax soo saarka dufcaddii yar-yar (muddada cusboonaysiinta ee qubeyska waa in ka badan 6 bilood), sababtoo ah xawaaraha cusboonaysiinta ee qubeyska waa mid aad u gaabis ah, xabagta ee qubeyska waa gabowga iyo walxaha dareere isbedel si weyn. Qubayska waa mid aan degganayn.

Tallaabooyinka Electrocoating

(1) Daahan electrophoretic ee sagxadaha biraha guud, socodka geedi socodka waa: pre-nadiifinta → hoos u dhigista → biyaha dhaqida → saarista miridhku → biyaha dhaqida → dhexdhexaad → biyaha dhaqida → fosfat → biyaha dhaqida → passivation → daahan electrophoretic → haanta sare Nadiifin → dhaqidda biyaha ultrafiltration → qallajin → offline.

(2) Substrate-ka iyo ka-hortagga shayga dahaarka leh ayaa saameyn weyn ku leh filimka daahan electrophoretic. Duubista birta ah guud ahaan waxaa dabar goynaya bacaad-qarxinta ama xabbad-qarxinta, dunta cudbi waxaa loo isticmaalaa in laga saaro boodhka sabbeynaya ee dusha sare ee shaqada, iyo warqad-cadeedka waxaa loo isticmaalaa in lagu saaro haraaga tallaalada birta ah iyo qashinka kale ee dusha sare yaal. Dusha birta ah waxaa lagu daaweeyaa hoos u dhigista iyo ka saarista miridhku. Marka shuruudaha dusha sare ay aad u sarreeyaan, fosfatinta iyo daaweynta dusha sare ee passivation ayaa loo baahan yahay. Biraha birta ah ee birta ah waa in lagu sameeyaa fosfooraska ka hor inta aan la helin electrophoresis anodic, haddii kale caabbinta daxalka ee filimka rinjiga ayaa noqon doona mid liita. Daawaynta fosfatinta, filimka fosfatinta cusbada ee zinc ayaa guud ahaan la doortaa, oo dhumucdiisu tahay 1 ilaa 2 μm, iyo filimka fosfatetada ayaa looga baahan yahay inuu yeesho kiristaalo fiican oo isku mid ah.

(3) Nidaamka sifaynta, sifaynta aasaasiga ah ayaa guud ahaan la qaatay, shaandheyntuna waa qaab-dhismeedka bacaha mesh. Rinjiga korantada waxaa lagu geeyaa shaandhada iyada oo loo sii marayo bam toosan si loo sifeeyo. Iyadoo la tixgelinayo wareegga beddelka ee dhammaystiran iyo tayada filimka rinjiga, bacda shaandhada leh cabbirka daloolka 50μm ayaa ah kan ugu fiican. Ma buuxin karto oo kaliya shuruudaha tayada filimka rinjiga, laakiin sidoo kale waxay xallin kartaa dhibaatada bacaha shaandhada.

(4) Cabbirka habka wareegga wareegga ee daahan electrophoretic ayaa si toos ah u saameeya xasilloonida qubeyska iyo tayada filimka rinjiga. Kordhinta mugga wareegga waxay yaraynaysaa roobabka iyo xumbo ee dareeraha qubayska; si kastaba ha ahaatee, gabowga dareeraha qubayska ayaa soo dedejiya, isticmaalka tamarta ayaa kordha, xasiloonida dareeraha qubayska ayaa sii xumaanaya. Waxay ku habboon tahay in la xakameeyo wakhtiyada wareegga dareeraha taangiga ilaa 6-8 jeer / h, taas oo aan dammaanad qaadin tayada filimka rinjiga, laakiin sidoo kale waxay hubisaa hawlgalka xasilloon ee dareeraha taangiga.

(5) Sida wakhtiga wax-soo-saarka uu kordho, xannibaadda diaphragm-ka anode-ka ayaa kordhin doonta iyo tamarta shaqada ee waxtarka leh ayaa hoos u dhigi doonta. Sidaa darteed, wax soo saarka, korantada hawlgalka ee tamarta korontada waa in si tartiib tartiib ah loo kordhiyo iyadoo loo eegayo khasaaraha danab si loo magdhabo dhibicda danab ee diaphragm anode.

(6) Nidaamka ultrafiltration wuxuu xakameynayaa fiirsashada ions wasakhda ah ee ay keento workpiece si loo hubiyo tayada daahan. Hawlgalka nidaamkan, waa in la ogaadaa in marka nidaamku shaqeynayo, waa inuu si joogto ah u shaqeeyaa waxaana si adag loo mamnuucay in uu si isdaba-joog ah u socdo si looga hortago in xuubka ultrafiltration uu u engego. Xabagta la qalajiyey iyo midabka ayaa ku dheggan xuubka ultrafiltration oo si fiican looma nadiifin karo, taas oo si weyn u saameyn doonta qulqulka biyaha iyo nolosha adeegga xuubka ultrafiltration. Heerka wax soo saarka biyaha ee xuubka ultrafiltration wuxuu muujinayaa isbeddel hoos u dhac ah oo leh wakhtiga socda. Waa in la nadiifiyaa hal mar 30-40 maalmood oo shaqo joogto ah si loo hubiyo biyaha ultrafiltration ee looga baahan yahay dheecaanka ultrafiltration iyo dhaqidda.

(7) Habka dahaarka electrophoretic ayaa ku habboon habka wax soo saarka ee tiro badan oo khadadka shirarka. Wareegga cusboonaysiinta ee qubeyska electrophoresis waa in ay ahaataa 3 bilood gudahood. Maareynta sayniska ee qubeyska ayaa aad muhiim u ah. Qaybaha kala duwan ee qubayska si joogto ah ayaa loo tijaabiyaa, qubayska waa la hagaajiyaa oo la beddelaa iyadoo loo eegayo natiijooyinka baaritaanka. Guud ahaan, xuduudaha xalka qubayska waxaa lagu qiyaasaa inta jeer ee soo socota: qiimaha pH, maadada adag iyo conductivity ee xalka electrophoresis, xalalka ultrafiltration iyo xal nadiifinta ultrafiltration, xal dabaysha (anode) , dareeraha wareega, iyo xal nadiifinta deionization hal mar. maalin; Saamiga saldhigga, waxa ku jira dareeraha organic, iyo shaybaarka tijaabada haanta yar ee laba jeer toddobaadkii.

(8) Si loo maamulo tayada filimka rinjiga waa in si joogto ah loo fiiriyaa isku mid ahaanshaha iyo dhumucda filimka rinjiga, muuqaalkuna waa inuusan yeelan dalool, dhogorta, diirka liinta, laalaabyada, iwm. Si joogto ah u hubi jirka iyo kiimikada. tilmaamayaasha sida adhesion iyo caabbinta daxalka ee filimka daahan. Wareegga kormeerku wuxuu waafaqsan yahay heerarka kormeerka soo saaraha, guud ahaanna qayb kasta waxay u baahan tahay in la eego.

Daaweynta dusha sare ee Electrophoresis ka hor

Daaweynta dusha sare ee workpiece ka hor daahan waa qayb muhiim ah oo ka mid ah daahan electrophoretic, inta badan ku lug leh xaalufinta, saarista miridhku, qaboojinta dusha, fosfatka iyo hababka kale. Tayada daaweynteeda kaliya ma saameynayso muuqaalka filimka, waxay yaraynaysaa waxqabadka ka hortagga daxalka, laakiin sidoo kale waxay burburisaa xasilloonida xalka rinjiga. Sidaa darteed, dusha sare ee workpiece ka hor rinjiyeynta, waxaa looga baahan yahay in ay xor ka yihiin wasakhda saliidda, calaamadaha miridhku, ma kiimikooyinka pretreatment iyo fosfat sedimentation, iwm, iyo filimka fosfattu wuxuu leeyahay kiristaalo cufan iyo lebis. Marka laga hadlayo hababka kala duwan ee daawaynta ka hor, ka hadli mayno iyaga si gaar ah, laakiin kaliya waxay soo bandhigaan dhowr qodob oo feejignaan ah:

1) Haddii hoos u dhigista iyo miridhku aanay nadiif ahayn, ma saameyn doonto oo kaliya sameynta filimka fosfatka, laakiin sidoo kale waxay saameynaysaa xoogga isku-xidhka, waxqabadka qurxinta iyo iska caabbinta daaha. Filimka rinjigu wuxuu u nugul yahay hoos u dhaca iyo godadka.

2) Fosfat: Ujeedadu waa in la wanaajiyo xabagta iyo awoodda ka-hortagga daxalka ee filimka electrophoretic. Doorkeedu waa sidan soo socota:

(1) Saamaynta jirka iyo kiimikaad awgeed, ku-xidhka filimka daahan organic ee substrate waa la wanaajiyey.

(2) Filimka phosphating wuxuu u rogayaa birta birta ah ee ka mid ah kirishbooyada wanaagsan ilaa kirishbooyada liidata, taas oo ka hortagaysa samaynta baytariyada yaryar ee dusha birta, si wax ku ool ah uga hortagga daxalka dahaarka, iyo kordhinta caabbinta daxalka iyo caabbinta biyaha ee daahan. Intaa waxaa dheer, kaliya iyada oo lagu saleynayo hoos u dhigista iyo hoos u dhigista, filim fosfit ah oo ku qanacsan ayaa lagu samayn karaa dusha nadiif ah, lebis, iyo dufan aan dufan lahayn. Marka laga eego dhinacan, filimka fosfatka laftiisa ayaa ah midka ugu dareenka badan oo la isku halleyn karo oo ku saabsan saameynta habka daaweynta ka hor.

3) Dhaqida: tayada dhaqida marxalad kasta oo ka mid ah pretreatment waxay saameyn weyn ku yeelan doontaa tayada dhammaan pretreatment iyo filimka rinjiga. Nadiifinta biyaha ee ugu danbeysa ka hor rinjiyeynta, hubi in dareeraha dareeraha ee shayga dahaarka leh aanu ka badnayn 30μs/cm. Nadiifintu ma nadiifsana, sida qalabka shaqada:

(1) Aashitada haraaga ah, dareeraha kiimikaad fosfat, qulqulaya xabagta dareeraha rinjiga, iyo xasilloonida oo sii xumaanaysa;

(2) Walxaha shisheeyaha ee haraaga ah (dharka saliidda, boodhka), godadka yaraynta, qaybaha iyo cilladaha kale ee filimka rinjiga;

(3) Electrolytes-ka hadhaaga ah iyo milixdu waxay horseedaan inay ka sii daraan falcelinta korantada waxayna soo saaraan godad iyo cuduro kale.

Waqtiga boostada: Abriil-17-2021