Kabka cawlan ee gaarka ahalaabta tuuraya caaryada qolofadeegyo lehMashiinka CNC, daaweynta kulaylka iyo daaweynta dusha sare.

Birta cawl, ama birta cawlan, waa nooc ka mid ah birta shubka ah oo leh qaab-dhismeed yar oo garaafeed ah. Waxaa lagu magacaabaa midabka cawl ee jabka uu sameeyo. Birta cawlan waxaa loo isticmaalaa guryaynta halka qallafsanaanta qaybtu ay ka muhiimsan tahay xooggeeda adkaysiga, sida matoorka gubashada gudaha ee blocks cylinders, guriyaha bamka, weelka waalka, sanduuqyada korantada, miisaanka miiska iyo shubka qurxinta. Kabka cawlan ee kulaylka sare ee birta iyo awooda madaxa gaarka ah ayaa inta badan laga faa'iideystaa in lagu sameeyo qalabka wax lagu karsado ee birta ah iyo rotors brake disc.

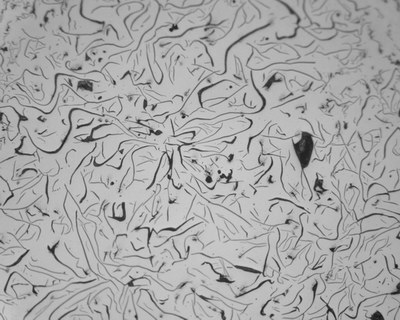

Halabuurka kiimikada caadiga ah si loo helo qaab-dhismeedka garaafyada garaafyada waa 2.5 ilaa 4.0% kaarboon iyo 1 ilaa 3% silikoon miisaan ahaan. Garaafka ayaa laga yaabaa inuu qabsado 6 ilaa 10% mugga birta cawl. Silikoonku waa muhiim in la sameeyo birta cawl oo ka soo horjeeda birta cad ee kabka, sababtoo ah silikoonku waa unug xasilin graphite ah oo ku jira birta birta ah, taas oo macnaheedu yahay in ay ka caawiso daawaha soo saarista graphite halkii ay ka heli lahayd carbide birta; 3% silikoon ku dhawaad kaarboon laguma hayo kiimikaad la socota birta.

Garaafku wuxuu qaataa qaabka jajab saddex-cabbir ah. Laba cabbir, sida dusha sare ee dhalaalaya ay ka soo muuqan doonto mikroskoob, jajabyada garaafka ayaa u muuqda sida xariiqyo fiican. Talooyinka jeexjeexyadu waxay u dhaqmaan sidii darajo hore u jiray; sidaas darteed, waa jajab. Joogitaanka garaafyada garaafyada ayaa ka dhigaysa Birta Gray si fudud mid lagu farsamayn karo maadaama ay u janjeeraan inay si fudud u dillaacaan jajabyada garaafka. Birta cawl waxa kale oo ay leedahay awood qoyan oo aad u wanaagsan, sidaa awgeed waxa inta badan loo isticmaalaa saldhigga rakibaadda mishiinka.

Astaamaha Makaanikada ee Birta Cas ee Cawlan | |||||||

| Shayga sida ku cad DIN EN 1561 | Cabbir | Unug | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Xoogga Jilicsan | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Xoogga Wax-soosaarka | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Xoogga Fidinta | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Xoog isku dhejisan | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Xoog Cadaadis ah | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Xoog Jilicsan | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Cadaadis xiiran | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules ee barti | E | GPA | 78 - 103 | 88 - 113 | 103 - 118 | 108 - 137 | 123 - 143 |

| Lambarka sunta | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| adkaanta brinell | HB | 160 - 190 | 180 - 220 | 190 - 230 | 200 - 240 | 210 - 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Xiisadda iyo cadaadiska ayaa isbeddela | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Xoogga Jebinta | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Cufnaanta | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

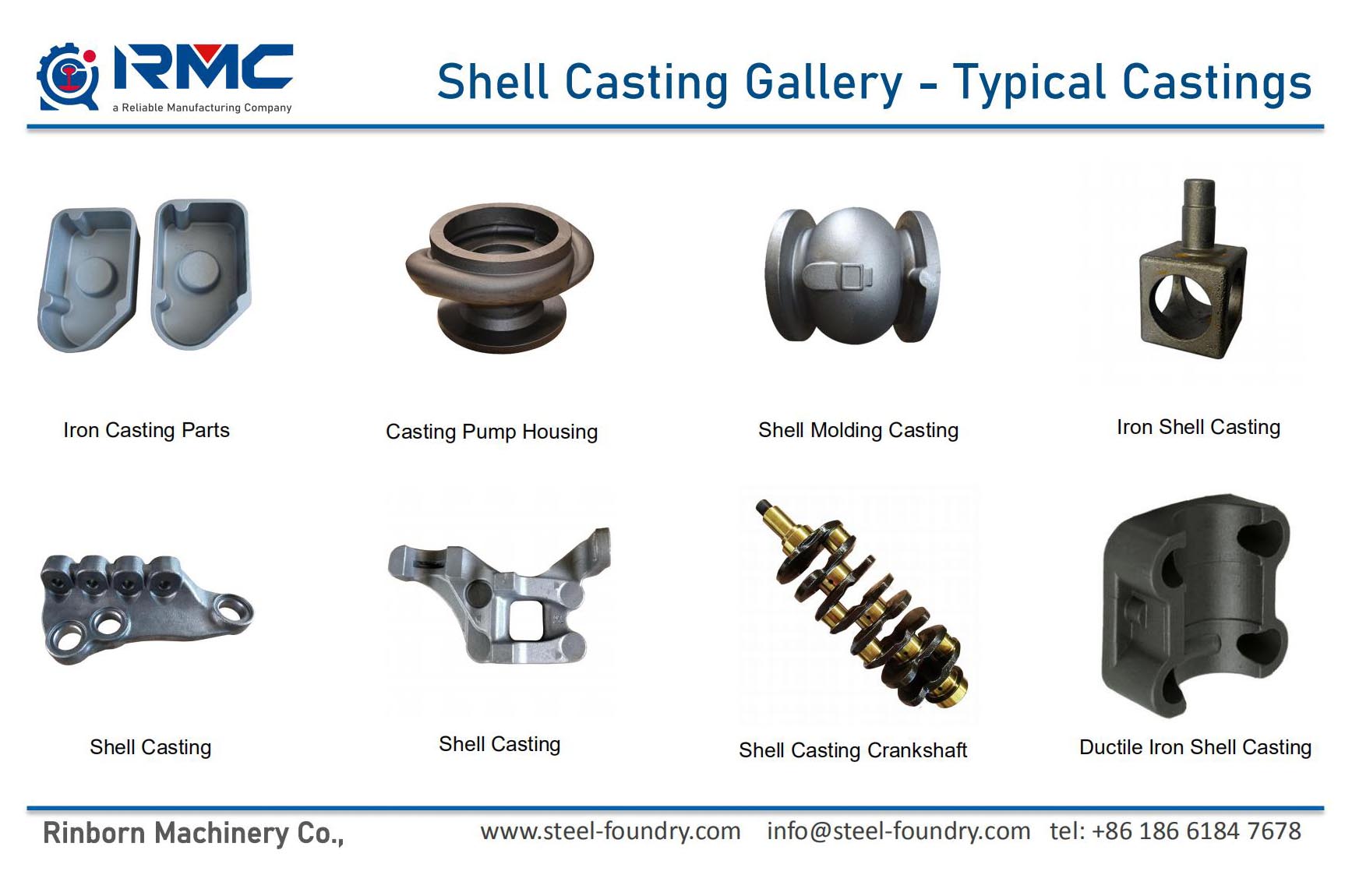

Dhalinta qolofkahabka waxa kale oo loo yaqaan habka shubista xabagta hore loo dahaadhay, shubista qolof kulul ama habka shubista xudunta u ah. Walaxda ugu weyn ee wax lagu dhejiyo waa ciidda xabagta phenolic ee horay loo dahaadhay, taas oo ka qaalisan ciidda cagaarka ah iyo ciidda xabagta furan. Waxaa intaa dheer, ciiddan dib loo warshadayn karo lama isticmaali karo.

Habka shubista ciidda is-adkeysiinaya resin Furan (nobake process) wuxuu isticmaalaa ciidda dahaarka leh ee furan si uu u sameeyo caaryada tuurista. Ka dib marka la qaso cammuudda asalka ah (ama ciidda dib loo soo celiyay), dareeraha furan ee dareeraha ah iyo dareeraha dareeraha si siman, oo ku buuxi sanduuqa xudunta u ah (ama sanduuqa ciidda), ka dibna adkee si aad u dhuujiso caaryada ama caaryada sanduuqa xudunta u ah (ama ciid). sanduuqa) heerkulka qolka. Dabadeed waxaa la sameeyay caaryada tuurista ama xudunta tuurista, taas oo loo yaqaanno is-adkeysi qabow-core sanduuqa (core), ama habka is-adkeysi (core).

Sababtoo ah caaryada waxay ku sameysan tahay heerkulka qolka oo aan loo baahnayn in lagu kululeeyo, isku-adkaynta ciidda isku-xoojinta waxaa sidoo kale loo yaqaan habka wax-dubidda. Habka is-adkeysigu waxa loo qaybin karaa xashiish-catalyzed furan resin-catalyzed iyo habka phenolic cammuudda is-adkeysi, habka is-adggeynta xabka kaadida iyo habka monoester is-adkeysi.

Ciidda sanduuqa qaboojiyaha ee is adkeeya, ciid xabagta furan ayaa ah tii ugu horreysay oo hadda loogu isticmaalka badan yahay ciid-xidhaha-isku-xidhaha ee Shiinaha. Qadarka resinka lagu daray ciidda wax-ku-beddelka guud ahaan waa 0.7% ilaa 1.0%, iyo xadiga resinka lagu daray ee ciidda xudunta u ah guud ahaan waa 0.9% ilaa 1.1%. Waxa ku jira aldehyde bilaashka ah ee xabagta furan waxa ay ka hoosaysaa 0.3%, warshadaha qaarna waxa ay hoos uga dhaceen 0.1%. Aasaaska Shiinaha, ciidda furan ee resin is adkeysi waxay gaartay heer caalami iyadoon loo eegin habka wax soo saarka iyo tayada dusha sare ee shubka.

U dhiganta Fasalka Cast Birta Cawlan | ||||||||

| AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 | GG-10 | Fasalka 100 | 0110-00 | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Fasalka 150 | 0115-00 | Ft 15 D | FG 15 | FC 150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Fasalka 200 | 0120-00 | Ft 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0.6025 | GG-25 | Fasalka 250 | 0125-00 | Ft 25 D | FG 25 | FC 250 | G 25 |

| A48-45B | 0.6030 | GG-30 | Fasalka 300 | 0130-00 | Ft 30 D | FG 30 | FC 300 | G 30 |

| A48-50B | 0.6035 | GG-35 | Fasalka 350 | 0135-00 | Ft 35 D | FG 35 | FC 350 | G 35 |

| A48-60B | 0.6040 | GG-40 | Fasalka 400 | 0140-00 | Ft 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | FCMW 330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | FCMP 490 | GMN 55 |

| A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | FCMP 590 | GMN 65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | FCMP 540 | - |

| A220-80002 | 0.8170 | GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | FCMP 690 | GMN 70 |

Biraha shubka Ciidda Resin Dahaarka leh iyo Aloysyada | |

| Bir & Alloys | Fasalka caanka ah |

| Birta Cast cawlan | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodular) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Birta Ductile Birta ee Austempered (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Birta Kaarboonka | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Birta Aan Lahayn | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Roobka Adag ee Birta Da'a, Duplex Steel |

| Aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Naxaas / Copper-ku-saleysan Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Heerka: ASTM, SAE, AISI, GOST, DIN, EN, ISO, iyo GB | |

Faa'iidooyinka Kaabista Dhalinta Isku-adkaynta ee Furan Resin Dahaarka leh:

1) Hagaajinta saxnaanta cabbirka ee shubista iyo qallafsanaanta dusha sare.

2) Adkeynta caaryada (core) ciid uma baahna qallajin, taas oo badbaadin karta tamarta, iyo sanduuqyada alwaax ama caag ah oo jaban ayaa sidoo kale la isticmaali karaa.

3) Ciidda is-adkeysigeedu way fududahay in la isku xidho oo burburto, si fudud loo nadiifiyo wixii la shubay, ciid duug ah ayaa dib loo warshadayn karaa oo dib loo isticmaali karaa, taas oo aad u yaraynaysa xoogga shaqada ee samaynta xudunta u ah samaynta, qaabaynta, ciiddu soo dhacayso, nadiifinta iyo isku xidhka kale. Way fududahay in la ogaado makaanaynta ama otomatiga.

4) Jajabka tirada badan ee resin ee ciidda waa 0.8% ~ 2.0% oo keliya, iyo qiimaha guud ee alaabta ceeriin waa yar yahay.

Sababtoo ah habka is-adkeysigu wuxuu leeyahay faa'iidooyin badan oo kor ku xusan oo gaar ah, habka is-adkeysigu looma isticmaalo oo keliya samaynta xudunta u ah, laakiin sidoo kale waxaa loo isticmaalaa dhejinta dhejinta. Waxay si gaar ah ugu habboon tahay hal qayb iyo wax-soo-saar yar yar, waxayna soo saari kartaa birta shubka ah, birta shubka ah iyo kuwa aan birta ahayn ee daawaha. Qaar ka mid ah aasaasayaasha Shiinaha ayaa si buuxda u beddelay caaryada ciidda engegan ee dhoobada ah, caaryada ciidda sibidhka, iyo qayb ahaan beddelay caaryada ciidda dhalada biyaha ah.

Alaabaha Casriga ah ee Casriga ah ee Birta