Alaabooyinka birta kabka cawl lehhabka shubista caaryada ciiddaiyo mashiinka CNC.

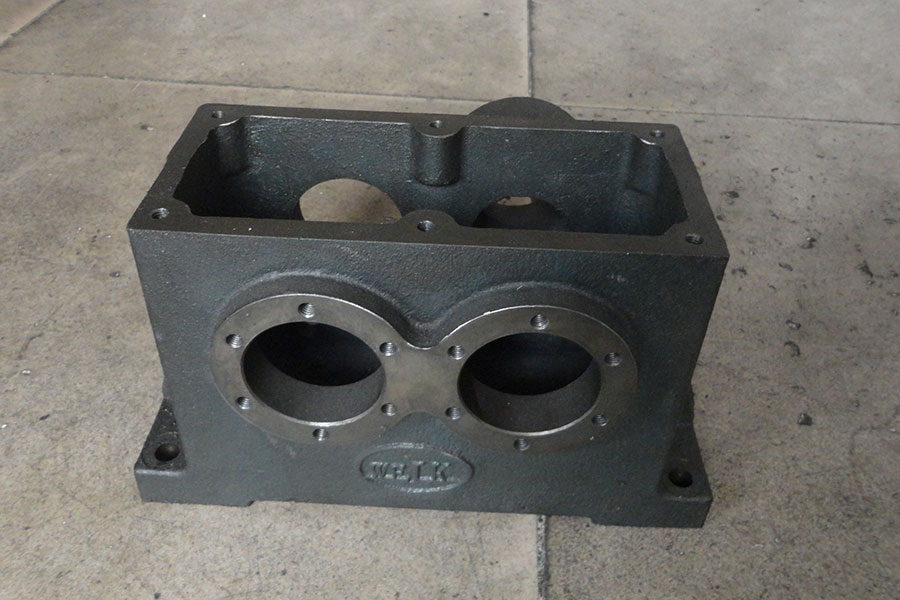

Birta kabka cawl waxa lagu magacaabaa midabka cawl ee jabka ay samayso. Birta cawlan waxaa loo isticmaalaa guryaynta halka qallafsanaanta qaybtu ay ka muhiimsan tahay xooggeeda adkaysiga, sida matoorka gubashada gudaha ee blocks cylinders, guriyaha bamka, weelka waalka, sanduuqyada korantada, miisaanka miiska iyo shubka qurxinta. Kabka cawlan ee kulaylka sare ee birta iyo awooda madaxa gaarka ah ayaa inta badan laga faa'iideystaa in lagu sameeyo qalabka wax lagu karsado ee birta ah iyo rotors brake disc.

Halabuurka kiimikada caadiga ah si loo helo qaab-dhismeedka garaafyada garaafyada waa 2.5 ilaa 4.0% kaarboon iyo 1 ilaa 3% silikoon miisaan ahaan. Garaafka ayaa laga yaabaa inuu qabsado 6 ilaa 10% mugga birta cawl. Silikoonku waa muhiim in la sameeyo birta cawl oo ka soo horjeeda birta cad ee kabka, sababtoo ah silikoonku waa unug xasilin graphite ah oo ku jira birta birta ah, taas oo macnaheedu yahay in ay ka caawiso daawaha soo saarista graphite halkii ay ka heli lahayd carbide birta; 3% silikoon ku dhawaad kaarboon laguma hayo kiimikaad la socota birta.

Garaafku wuxuu qaataa qaabka jajab saddex-cabbir ah. Laba cabbir, sida dusha sare ee dhalaalaya ay ka soo muuqan doonto mikroskoob, jajabyada garaafka ayaa u muuqda sida xariiqyo fiican. Talooyinka jeexjeexyadu waxay u dhaqmaan sidii darajo hore u jiray; sidaas darteed, waa jajab. Joogitaanka garaafyada garaafyada ayaa ka dhigaysa Birta Gray si fudud mid lagu farsamayn karo maadaama ay u janjeeraan inay si fudud u dillaacaan jajabyada garaafka. Birta cawl waxa kale oo ay leedahay awood qoyan oo aad u wanaagsan, sidaa awgeed waxa inta badan loo isticmaalaa saldhigga rakibaadda mishiinka.

Guryaha Makaanikada Birta Cast | |||||||

| Shayga sida ku cad DIN EN 1561 | Cabbir | Unug | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Xoogga Jilicsan | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Xoogga Wax-soosaarka | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Xoogga Fidinta | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Xoog isku dhejisan | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Xoog Cadaadis ah | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Xoog Jilicsan | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Cadaadis xiiran | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules ee barti | E | GPA | 78 - 103 | 88 - 113 | 103 - 118 | 108 - 137 | 123 - 143 |

| Lambarka sunta | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| adkaanta brinell | HB | 160 - 190 | 180 - 220 | 190 - 230 | 200 - 240 | 210 - 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Xiisadda iyo cadaadiska ayaa isbeddela | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Xoogga Jebinta | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Cufnaanta | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Bacaad tuurista waxay isticmaashaa ciid cagaaran (ciid qoyan) ama ciid qalalan si ay u samaysato hababka qaabaynta. Tuurista ciid cagaaran waa habka wax tuurista ee duugga ah ee taariikhda loo isticmaalo. Marka la samaynayo caaryada, qaababka ka samaysan alwaax ama birta waa in la soo saaraa si loo sameeyo godka bannaan. Birta dhalaalaysa dabadeed ku shub godka si ay u sameeyaan shubka ka dib qaboojinta iyo adkaynta. Dhoofinta ciiddu way ka qaalisan tahay hababka kale ee wax shubista labadaba horumarinta caaryada iyo qayb ka bixinta halbeegga. Ciidda tuurista, had iyo jeer waxay ka dhigan tahay tuurista ciidda cagaaran (haddii aysan jirin sharraxaad gaar ah). Si kastaba ha ahaatee, maalmahan, hababka kale ee wax shubista ayaa sidoo kale loo isticmaalaa ciidda si ay u sameeyaan caaryada. Waxay leeyihiin magacyo u gaar ah, sidatuurista caaryada qolof, shub cammuudda dahaarka leh resin furan (nooca dubista ma jiro),luntay xumbo tuuridiyo tuurista vacuum.

Awoodaha Kabka Ciidda ee Xarunta RMC | ||

| Sharaxaada | Ku qaabaynta buug-gacmeedka | Naqshadeynta Mashiinnada Atoomatiga ah |

| Cabirka ugu badan ee jilitaanka | 1,500 mm × 1000 mm × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Qiyaasta Miisaanka Qaadista | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Awood Sannadeedka | 5,000 oo tan - 6,000 oo tan | 8,000 oo tan - 10,000 oo tan |

| Dulqaadashada | Codsiga ama Heerka (ISO8062-2013 ama GB/T 6414-1999) | |

| Qalabka wax lagu dhejiyo | Ciid Cagaaran, Ciid Dahaar ah oo Been ah | |

| Duubista Birta & Aloysyada | Birta Cawlan, Birta Ductile, Birta Cast, Birta Aan Lahayn, Alloys, Brass, Bronze...iwm. | |

Faa'iidooyinka Ciidda tuurista:

- ✔ Kharash yar oo ay ugu wacan tahay alaabteeda caaryada ah oo jaban oo dib loo warshadayn karo iyo qalabka wax soo saarka ee fudud.

- ✔ Miisaanka halbeeg ballaaran laga bilaabo 0.10 kg ilaa 500 kgs ama xitaa ka weyn.

- ✔ Qaab dhismeed kala duwan laga bilaabo nooca fudud ilaa nooc kakan.

- ✔ Ku haboon shuruudaha wax soo saarka ee tiro kala duwan.

Dulqaadka ay ku gaadhaan Kacitaanka Ciidda:

Dulqaadyada kabka waxa loo qaybiyaa Dulqaadashada Qaadashada Cabbirka (DCT) iyo Dulqaadyada Qaadashada Joomatari (GCT). Aasaaskayagu wuxuu jeclaan lahaa inuu kula hadlo haddii aad hayso codsi gaar ah oo ku saabsan dulqaadka loo baahan yahay. Halkan kuwan soo socda ayaa ah darajada dulqaadka guud ee aanu ku gaadhi karno tuurista ciidda cagaaran, shubista caaryada qolofka ah iyo shubista ciidda xabagta furan ee aan la duban:

- ✔ Darajada DCT ee Cagaar Cagaar Kaabista: CTG10 ~ CTG13

- ✔ Darajada DCT ee Shell Mold tuurista ama Kaabista Ciidda Furan Resin Ciid: CTG8 ~ CTG12

- ✔ Fasalka GCT ee Cagaaran Sand Casting: CTG6 ~ CTG8

- ✔ GCT darajada by Shell Mold tuurista ama Furan Resin Ciid tuurista: CTG4 ~ CTG7

Fasalka Birta & Alloys-ka ee Hannaanka Kabista Ciidda | |

| Bir & Alloys | Fasalka caanka ah |

| Birta Cast cawlan | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodular) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Birta Ductile Birta ee Austempered (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Birta Kaarboonka | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Birta Aan Lahayn | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Roobka Adag ee Birta Da'a, Duplex Steel |

| Aluminium Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Naxaas / Copper-ku-saleysan Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Heerka: ASTM, SAE, AISI, GOST, DIN, EN, ISO, iyo GB | |

-

Badeecada Cast Birta Cast Gray

-

Alaabada jilitaanka qolofta cawlan ee birta

-

OEM Gray Cast Iron Casting

-

Alloy Steel Resin Dahaarka leh Ciidda Kaabista Crankshaft

-

Alloy Steel Ciid jilbisyada

-

Qaybaha Gawaadhida Gawaadhida Daawaha ah ee ay Sameeyaan Kabka Ciidda iyo CNC

-

Shirkadda Casriyeynta Birta Carbon Carbon

-

Cast Steel Ciid Kaabista

-

Aluminium Alloy Ciidda Casting