Guryaha waalka gaarka ah ee birta duplex-ga ah ee ay soo saartay maal-gashi ka soo shubista Shiinaha oo lehmakiinado, daaweynta kulaylka, iyo adeegyada daaweynta oogada.

RMCqaybo bir ah oo sax ahsi joogto ah u buuxiya ama dhaafsiisan filashooyinka macaamiisha. Kaabista maalgashiga dhunka ee lumay ayaa noo ogolaanaysa inaan soo saarnoalaabta shubka birta ahamain ka yar sida tobanaan garaam iyo ka weyn sida tobanaan kiiloogaraam, oo ah noocyo kala duwan oo bir ah iyo kuwa aan bir ah lahayn oo leh saxnaansho cabbir gaar ah.

Geedi socodka shubista dhubada ee luntay waxay soo saartaa qaab-dhismeedka saxda ah ee u dhow oo inta badan u baahan wax yar ama aan lahayn mashiin dheeri ah. Dhammaadka ka soo baxay ayaa sidoo kale aad uga wanaagsan waxa lagu gaari karo qaab shubasho ama wax soo saar kale. Awooda iyo adkeysiga qaybaha wax shubista ayaa naftooda ka dhigaya kuwo ku habboon codsiyada adkaysiga sare ee u baahan malaayiin wareeg ah.

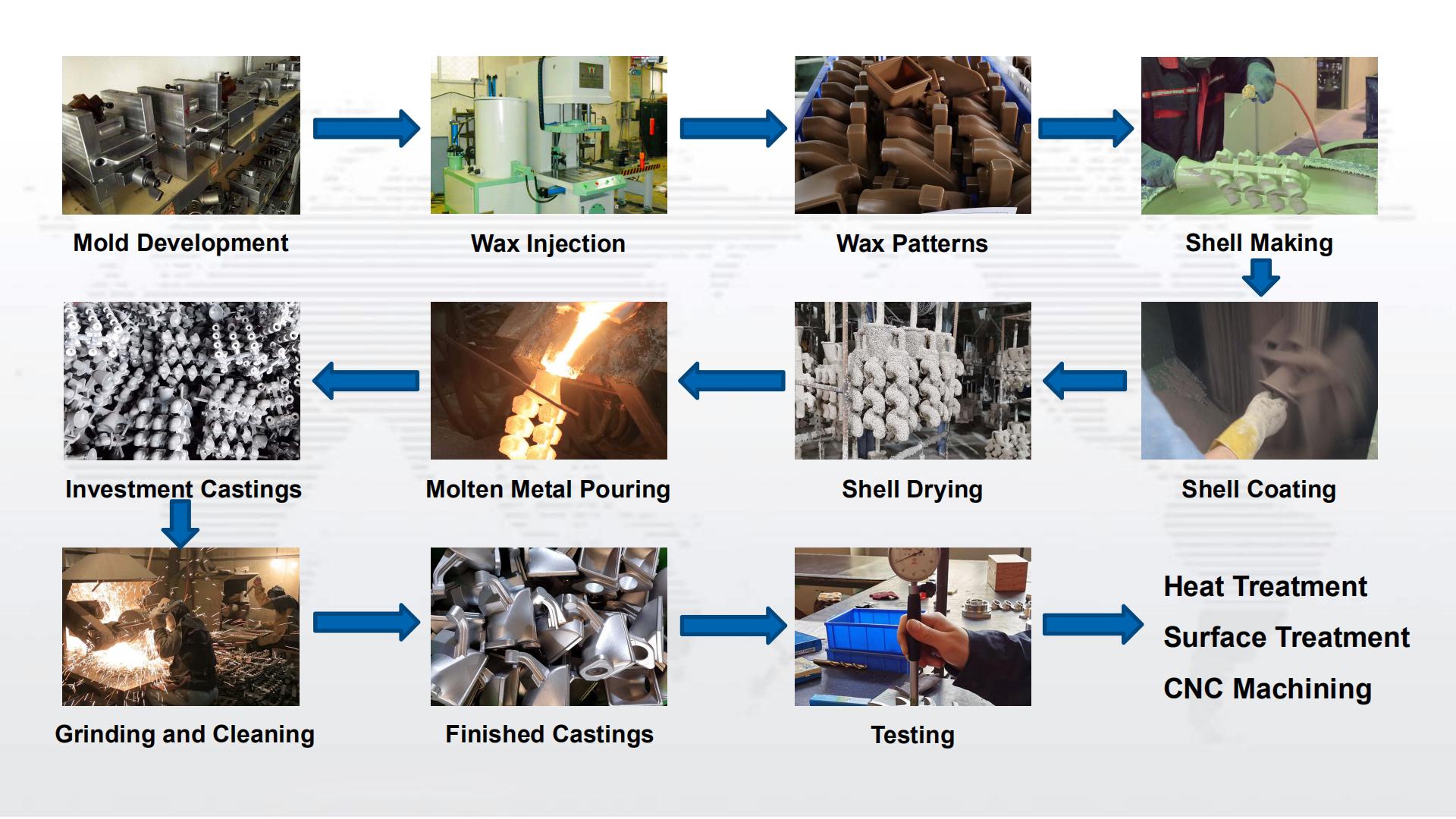

Tillaabooyinka Habka Qaadista Maalgelinta:

Inta lagu jiro habka shubista maalgashiga, qaabka wax-soo-saarka ayaa lagu dahaadhay walxo dhoobo ah, kaas oo, marka la adkeeyo, qaata joomatari gudaha ah ee tuurista la rabo. Xaaladaha intooda badan, qaybo badan ayaa la isku daraa si ay waxtar sare u yeeshaan iyada oo lagu dhejiyo qaababka shayga gaarka ah ul dhexe ee loo yaqaan sprue. Dhuka ayaa ka dhalaalay qaabka - waana sababta loo yaqaan habka dhunka lumay - iyo biraha dhalaalay ayaa lagu shubaa godka. Marka birta ay adkaato, caaryada dhoobada waa la ruxayaa, taasoo ka tagaysa qaabka saafiga ah ee u dhow ee tuurista la rabo, oo ay ku xigto dhamaystirka, tijaabinta iyo baakadaha.

Duplex Stainless Steel (DSS) waxaa loola jeedaa birta aan birta lahayn ee ferrite iyo austenite mid kasta oo xisaabinaysa ilaa 50%. Guud ahaan, nuxurka wejiyada yar waxay u baahan yihiin ugu yaraan 30%. Marka laga hadlayo maadada C ee hoose, waxa ku jira Cr waa 18% ilaa 28%, Nina waxa ku jira 3% ilaa 10%. Qaar ka mid ah birta aan lahayn laba-laabka ah ayaa sidoo kale ka kooban walxo alloying ah sida Mo, Cu, Nb, Ti, iyo N.

Darajada laga heli karo birta duplex ee birta ah ee RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A 5A 8A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS waxay leedahay sifooyinka birta aan lahayn ee austenitic iyo ferritic. Marka la barbar dhigo ferrite, waxay leedahay caag sare iyo ductility, ma laha heerkul qolka qolka, oo si weyn u wanaajiyay iska caabinta daxalka intergranular iyo waxqabadka alxanka, iyadoo wali la ilaalinayo jajabnaanta, kuleylka kuleylka sare, iyo superplasticity sida birta ferrite. Marka la barbar dhigo birta daxalka ah ee austenitic, DSS waxay leedahay awood sare waxayna si weyn u wanaajisay iska caabbinta daxalka intergranular iyo daxalka culayska koloridhida. Birta aan lahayn Duplex waxay leedahay iska caabin daxalka oo aad u wanaagsan sidoo kale waa bir aan lahayn nikkel badbaadinaysa.

| Heerka u dhigma ee birta aan lahayn | |||||||

| KOOXAHA | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic iyo Ferritic Stainless Steel | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 Crs 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Biraha birta ah iyo kuwa aan birta ahayn ee loogu talagalayMaalgelinta Maalgelinta, Geedi socodka shubista Dhuxista:

• Birta cawlan: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Birta Ductile ama Birta Nodular: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Birta Kaarboon: AISI 1020 - AISI 1060, C30, C40, C45.

• Biraha birta ah: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...iwm marka la codsado.

• Birta aan lahayn: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 iyo kuwa kale ee darajada birta ah.

Naxaasta, Naxaasta Cas, Bronze ama biraha kale ee ku salaysan Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

Qalabka kale sida shuruudahaaga gaarka ah ama sida waafaqsan ASTM, SAE, AISI, ACI, DIN, EN, ISO, iyo heerarka GB

▶ AwoodahaAasaaska Maalgelinta Maalgashiga

• Cabirka ugu badan: 1,000 mm × 800 mm × 500 mm

• Qiyaasta Miisaanka: 0.5 kg - 100 kg

• Awood Sannadeedka: 2,000 oo tan

• Qalabka dammaanadda ee Dhismaha Shell: Silica Sol, Muraayadaha Biyaha iyo isku-darkooda.

| Adeegyada | Sharaxaada |

| Adeegyada Daawaynta Dusha sare | Dahaarka budada, Anodization, Electrophotesis, Chrome Plating, Rinjiyeynta, Ciidda qarxinta, Plating Nickel Plating, Plating Zinc, Blacking, Polishing, Bluing, Geormet, Zintek, iwm. |

| Adeegyada Mashiinnada Saxda ah ee CNC | Dhaqidda, wax-shiidka, leexinta, hufnaanta, qodista, caajiska ah, garaacista, Goynta Siliga Korontada, Shiidida...iwm. |

| Kormeerka iyo Xakamaynta Tayada | Falanqeeyaha Spectrum, CMM, Tijaabada Adag, Tijaabada Xoog-Xoojinta, Yild Strentgh Testor, Tijaabada Cadaadiska, Falanqeeyaha Kaarboon Sulfur, Mikroskoobyada Metallurgical, Tijaabada Awooda Saxafada...iwm. |