Sida caadiga ah, birta aan-ka-soo-saarka lahayn waa in lagu tuuraahabka shubista saxda ah ee maalgashigaoo leh silica sol sida curaarta. Shubadaha silica sol ee aan birta lahayn waxay leeyihiin darajo aad u sarreeya oo sax ah oogada iyo waxqabadka.

Sababo la xiriira sifooyinka jireed ee gaarka ah,shubka birta ahamawaxay caan ku yihiin codsiyo badan oo kala duwan, gaar ahaan kuwa ku sugan deegaan adag. Suuqyada caadiga ah ee shubista maalgashiga birta aan-daba-marin waxaa ka mid ah saliidda iyo gaasta, awoodda dareeraha, gaadiidka, nidaamyada hawo-biyoodka, warshadaha cuntada, qalabka iyo qufullada, beeraha ... iwm.

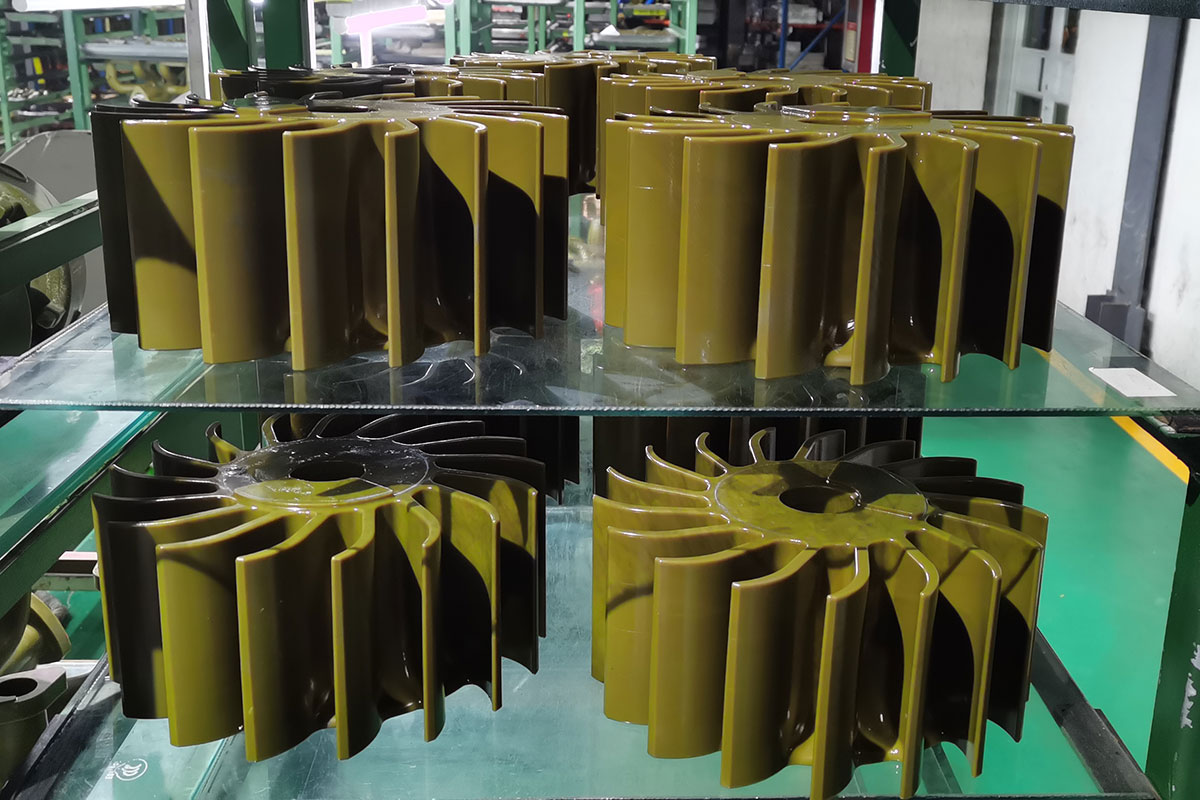

Maalgelinta (wax lumay) wax shubiddu waa habka saxda ah ee loo shubo tafaasiisha qaabka shabagga dhow ee isku dhafan iyadoo la isticmaalayo qaabaynta shaabka. Ku shubista maalgashiga ama dhunka lumay waa habka samaynta birta oo sida caadiga ah adeegsata qaabka dhuka oo ay ku wareegsan yihiin qolof dhoobada si ay u sameeyaan caaryada dhoobada. Marka qolofku engego, dhukayagu wuu dhalaali doonaa, isaga oo ka tagaya oo kaliya caaryada. Kadibna qaybta wax shubista ayaa la sameeyayadigoo ku shubaya bir dhalaalaysa caaryada dhoobada ah.

Nidaamku wuxuu ku habboon yahay wax soo saarka soo noqnoqda ee qaybaha qaabka saafiga ah ee ka soo baxa biraha kala duwan ee kala duwan iyo daawaha waxqabadka sare. In kasta oo guud ahaan loo isticmaalo tuurista yaryar, habkan waxa loo isticmaalay in lagu soo saaro albaabbada dayuuradaha oo dhammaystiran, iyada oo birta lagu shubay ilaa 500 kgs iyo aluminium tuuryo ilaa 50kg ah. Marka la barbardhigo hababka kale ee wax shubista sida tuurista dhinta ama ciid tuurista, waxay noqon kartaa habraac qaali ah. Si kastaba ha ahaatee, qaybaha la soo saari karo iyadoo la isticmaalayo shubista maalgelinta ayaa ku dari kara jaangooyooyin adag, inta badanna qaybaha waxaa lagu tuuraa meel u dhow qaabka saafiga ah, markaa waxay u baahan yihiin wax yar ama dib-u-shaqayn marka la shubo.

Habka shubista Silica Sol waa habka maalgelinta birta ee ugu weyn ee RMCFoundry kabka maalgashiga. Waxaan horumarinaynay tignoolajiyada cusub ee walxaha koollada si aan u gaarno wax badan oo dhaqaale iyo wax ku ool ah oo koollo ah si loo dhiso qolofka slurry. Waa isbeddel xad dhaaf ah in habka shubista Silica sol uu beddelo habka dhalada biyaha hoose ee qallafsan, gaar ahaan shubista birta aan fiicnayn iyo shubista birta daawaha ah. Marka laga soo tago walxaha cusub ee wax lagu dhejiyo, habka shubista silica sol sidoo kale waa la cusboonaysiiyay iyada oo kuleylkeedu uu sii yaraanayo.

▶ Qalabyada Feeraska ah iyo kuwa Aan-ferrouska ahayn ee Maalgelinta Maalgelinta, Geedi socodka shubista Dhuxista:

• Bir cawlanHT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Birta Ductile ama Birta Nodular:GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Birta Kaarboon:AISI 1020 - AISI 1060, C30, C40, C45.

• Aloysyada Birta:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... iwm haddii la codsado.

• Birta Aan Lahayn:AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 iyo kuwa kale ee birta ah.

Naxaasta, Naxaasta Cas, Bronze ama Biraha Alloynka kale ee Copper ku salaysan:ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

Qalabka kale sida shuruudahaaga gaarka ah ama sida waafaqsan ASTM, SAE, AISI, ACI, DIN, EN, ISO, iyo heerarka GB

▶ Awoodaha Aasaaska Maalgelinta Maalgashiga

• Cabirka ugu badan: 1,000 mm × 800 mm × 500 mm

• Qiyaasta Miisaanka: 0.5 kg - 100 kg

• Awood Sannadeedka: 2,000 oo tan

• Qalabka dammaanadda ee Dhismaha Shell: Silica Sol, Muraayadaha Biyaha iyo isku-darkooda.

Dulqaadyada: Codsiga.

▶ Habka Wax-soo-saarka ugu Muhiimsan

Qaababka & Naqshadeynta Qalabaynta → Samaynta Birta Dhimashada → Duritaan Dhuxul → Dhisidda Shell → De-Waxing → Falanqaynta Halabuurka Kiimikada → Dhallaanka & Daadinta

▶ KormeeridTuubooyin Dhuxul Dhumay

• Falanqaynta tirade Spectrographic iyo gacanta

• Falanqaynta Metallographic

• Brinell, Rockwell iyo Vickers kormeerka adkaanta

• Falanqaynta hantida makaanikada

• Baaritaanka saameynta heerkulka hooseeya iyo kan caadiga ah

• Kormeerka nadaafadda

• Kormeerka UT, MT iyo RT

▶ Habka jilitaanka ka dib

• Deburinta & Nadiifinta

• Xabad Qarxaysa / Carrada Ciidda

• Daawaynta kulaylka: Caadiyan, Demmin, Heer-kulul, Carburization, Nitriding

• Daawaynta dusha sare: Passivation, Anodizing, Electroplating, Zinc Plating Hot, Plating Zinc Plating, Plating Nickel Plating, Polishing, Electro Polishing, Painting, GeoMet, Zintec.

• Makiinada: leexinta, wax-shiidka, dhaqidda, qodista, sharafta, shiididda.

▶ Faa'iidooyinka Qaybaha Maalgelinta:

• Dhamaystir dusha sare oo aad u wanaagsan oo siman

• Dulqaad adag oo cabbir ah.

• Qaabab adag oo qalafsan oo leh dabacsanaan nashqad

• Awoodda lagu tuuri karo gidaarrada khafiifka ah, sidaas awgeed waa qayb ka fudud oo wax tuurista ah

• Xulasho balaadhan oo ah biraha shubka ah iyo alloysyada (ferrous iyo non-ferrous)

• Qabyo loogama baahna naqshadaynta caaryada.

• Yaree baahida mashiinada labaad.

• Qashinka alaabta hoose.

▶ Waa maxay sababta aad RMC ugu dooratay Qaybaha shubista Dhuxista Gaarka ah?

• Xalka buuxa ee hal alaab-qeybiye oo u dhexeeya nashqad qaabaysan oo la habeeyey ilaa kabka la dhammeeyey iyo habka labaad oo ay ku jiraan farsamaynta CNC, daaweynta kulaylka iyo daaweynta dusha sare.

• Soo jeedinta qiima dhimista ee injineeradayada xirfadlayaasha ah ee ku salaysan shuruudahaaga gaarka ah.

• Waqti gaaban oo horudhac ah oo loogu talagalay prototype, tijaabinta tijaabinta iyo horumar kasta oo farsamo oo suurtagal ah.

• Walxaha xidhan: Silica Col, Muraayadaha Biyaha iyo isku-darkooda.

• Samaynta dabacsanaan ee amarrada yaryar ee amarrada tirada badan.

• Awoodaha wax soo saarka dibadda ee xooggan.