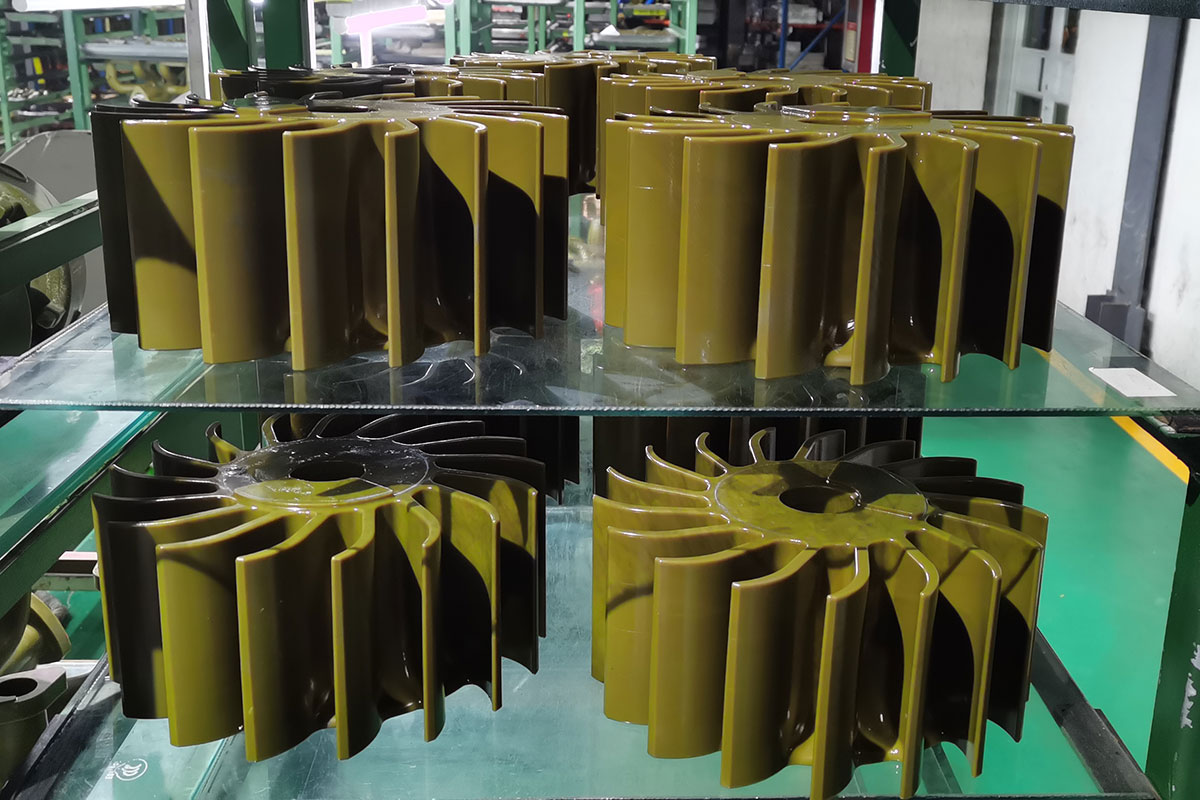

China OEM caado ahama impeller byhabka shubista maalgashiga dhunka lumay.

Walxaha daawaha aasaasiga ah ee wax kasta oo nikkel-saldhig ama ahama ahama shubista maalgelinta birta waa chromium, nikkel, iyo molybdenum (ama "moly"). Saddexdan qaybood ayaa go'aamin doona qaab dhismeedka hadhuudhka iyo sifada makaanikada waxayna noqon doonaan qalab wax ku shubista awooda kulaylka, xidhashada, iyo daxalka.

Birta aan-dhalatada lahayn ayaa leh ugu yaraan 10.5% ka kooban chromium, taas oo ka dhigaysa mid adkaysi u leh bay'adaha dareeraha wasakhaysan iyo oksaydhka. Si kastaba ha ahaatee, tani ma aha mid dhamaystiran. Maalgelinta birta aan-dhalatada lahaynshubashadu waa "daxalka u adkaysta" marka lagu isticmaalo jawi dareere ah iyo uumiga ka hooseeya 1200°F (650°C) iyo "kuleelka u adkaysta" marka la isticmaalo heer kulkan ka sarreeya.

Faa'iidooyinka Qaybaha Maalgelinta:

- Dhammaystir dusha sare oo heer sare ah oo siman

- Dulqaad adag oo cabbir ah.

- qaabab isku dhafan oo qalafsan oo leh dabacsanaan naqshadeed

- Awoodda lagu tuuro gidaarada khafiifka ah, sidaas awgeed waa qayb ka fudfudud

- Xulasho ballaadhan oo ah biraha la shubay iyo alloys (ferrous iyo non-ferrous)

- Qabyo looma baahna naqshadaynta caaryada.

- Iska yaree baahida mashiinada labaad.

- Qashinka alaabta hoose.

| Qalabka loogu talagalayMaalgelinta MaalgelintaGeedi socodka atAasaaska RMC | |||

| Qaybta | Heerka Shiinaha | Heerka US | Heerka Jarmalka |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic ahama | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404.8. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Roobab Adkeynaysa Birta Aan Lahayn | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Qalabka Birta | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Birta u adkaysata kulaylka | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy-saldhigga Nickle | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Daawaha Copper | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-saldhig Alloy | UMC50, 670, Fasalka 31 | 2.4778 | |

| Dulqaadyada MAALGASHIGA | |||

| Inches | millimitir | ||

| Cabirka | Dulqaad | Cabirka | Dulqaad |

| Ilaa 0.500 | ±.004" | Ilaa 12.0 | ± 0.10mm |

| 0.500 ilaa 1,000” | ±.006" | 12.0 ilaa 25.0 | ± 0.15mm |

| 1.000 ilaa 1.500” | ±.008" | 25.0 ilaa 37.0 | ± 0.20mm |

| 1.500 ilaa 2,000” | ±.010" | 37.0 ilaa 50.0 | ± 0.25mm |

| 2.000 ilaa 2.500” | ±.012" | 50.0 ilaa 62.0 | ± 0.30mm |

| 2.500 ilaa 3.500” | ±.014" | 62.0 ilaa 87.0 | ± 0.35mm |

| 3.500 ilaa 5,000” | ±.017" | 87.0 ilaa 125.0 | ± 0.40mm |

| 5.000 ilaa 7.500” | ±.020" | 125.0 ilaa 190.0 | ± 0.50mm |

| 7.500 ilaa 10,000" | ±.022" | 190.0 ilaa 250.0 | ± 0.57mm |

| 10.000 ilaa 12.500" | ±.025" | 250.0 ilaa 312.0 | ± 0.60mm |

| 12.500 ilaa 15.000 | ±.028" | 312.0 ilaa 375.0 | ± 0.70mm |