Birta daxalka u adkaysata, oo sidoo kale loo yaqaan kabka birta aan lahayn, waxa loola jeedaa birta kabka ee alloy-ka oo muujisa iska caabbinta daxalka ee noocyo kala duwan oo warbaahin gaar ah oo gaar ah ama deegaan ay ku wada nool yihiin daxalka iyo waxyaalaha farsamada.

| Aragtida Degdegga ah ee Birta Aan Lahayn ee Austenitic | |

| Halabuurka Kiimikada Ugu Weyn | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Waxqabadka | Aan magnet-ka ahayn, adayg sare, caag sare, xoog hoose |

| Qeexid | Birta aan fiicnayn ee leh qaab-dhismeedka austenitic ee heerkulka qolka |

| Darajooyinka Matalaada | 304, 316, 1.4310, 1.4301, 1.4408 |

| Mashiinka | Cadaalad |

| Weldability | Guud ahaan aad u wanaagsan |

| Isticmaalka Caadiga ah | Mashiinnada cuntada, Qalabka, Habaynta Kiimikada...iwm |

Birta aan-dhalatada lahayn ayaa leh ugu yaraan 10.5% ka kooban chromium, taas oo ka dhigaysa mid adkaysi u leh bay'adaha dareeraha wasakhaysan iyo oksaydhka. Aad bay u adkaysa daxalka waxayna xidhataa adkaysi, waxay bixisaa mashiin aad u fiican, waxayna caan ku tahay muuqaalkeeda bilicda. Tuubadaha maalgashiga ee birta-la'aanta ah waa "daxalka u adkaysta" marka lagu isticmaalo jawi dareere ah iyo uumiga ka hooseeya 1200°F (650°C) iyo "kuleelka u adkaysta" marka loo isticmaalo in ka sarreeya heerkulkan.

Austenitic ahamawaxaa loola jeedaa birta aan la taaban karin ee leh qaab-dhismeedka austenitic ee heerkulka qolka. Birta aan birta lahayn ee Austenitic waa mid ka mid ah shanta fasal ee ahama birta qaab dhismeedka crystalline (oo ay weheliso ferritic, martensitic, duplex iyo roobab adag). Meelaha qaarkood, birta austenite waxaa sidoo kale loo yaqaan 300 taxane ahama birta. Marka birta ay ka kooban tahay qiyaastii 18% Cr, 8% -25% Ni, iyo qiyaastii 0.1% C, waxay leedahay qaab dhismeed austenite deggan. Austenitic chromium-nickel steel-ka waxaa ka mid ah birta caanka ah ee 18Cr-8Ni iyo birta taxanaha ah ee Cr-Ni ee la sameeyay iyadoo lagu darayo nuxurka Cr iyo Ni laguna daray Mo, Cu, Si, Nb, Ti iyo walxo kale. Birta aan birta lahayn ee Austenitic waa mid aan magnet-ka ahayn oo waxay leedahay adayg sare iyo caag, laakiin xooggeedu waa hooseeyaa, mana aha wax aan suurtagal ahayn in lagu xoojiyo iyada oo loo marayo isbeddelka wajiga. Waxa kaliya oo lagu xoojin karaa qabow shaqaynta. Haddii walxaha sida S, Ca, Se, Te lagu daro, waxay leedahay sifooyin wanaagsan oo mashiinnada.

Birta aan lahayn Austenitic waxay sidoo kale soo saari kartaa shubid. Si loo hagaajiyo dareeraha birta dhalaalaysa loona wanaajiyo waxqabadka shubista, isku dhafka daawaha ee birta shubka ah waa in lagu hagaajiyaa iyada oo la kordhinayo maadada silikoon, la kordhinayo tirada chromium iyo nikkel, iyo kordhinta xadka sare ee baaruudka curiyaha wasakhda ah.

Austenitic ahama waa in lagu daaweeyaa adag-xalka ka hor inta aan la isticmaalin, si loo kordhiyo xal adag ee da'da kala duwan sida karbides ee birta galay matrix austenite ah, halka sidoo kale homogenizing qaab-dhismeedka iyo baabi'inta stress, si loo hubiyo in iska caabin daxalka aad u fiican iyo sifooyinka farsamada. Habka daawaynta saxda ah ee xalku waa qaboojinta biyaha kadib kuleylka 1050~1150℃ (qaybaha khafiifka ah sidoo kale waa la qaboojin karaa). Heerkulka daawaynta xalku waxay kuxirantahay heerka alloying ee birta: Darajooyinka birta aan lahayn molybdenum ama molybdenum-yar waa inay ahaadaan kuwo hooseeya (≤1100℃), iyo darajooyinka daawaynta sare sida 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, iwm. 1080~1150) ℃).

Austenitic 304 saxan bir ah oo bir ah, kaas oo la sheegay inuu keeno iska caabin adag oo ka hortagga miridhku iyo daxalka, wuxuuna leeyahay caag aad u fiican iyo adayg, kaas oo ku habboon shaabadeynta iyo samaynta. Iyada oo cufnaanta 7.93 g / cm3, 304 birta aan dahsoon waa bir aad u caadi ah, oo sidoo kale loo yaqaan 18/8 birta aan daahin ee warshadaha. Alaabooyinka birta ah waxay u adkeysanayaan heerkulka sare waxayna leeyihiin sifooyin wax ku ool ah oo wanaagsan, sidaas darteed waxaa si ballaaran loogu isticmaalaa warshadaha iyo warshadaha qurxinta alaabta guriga iyo warshadaha cuntada iyo caafimaadka.

Heerka u dhigma ee birta aan lahayn | |||||||

| Qaybaha | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic iyo Ferritic Stainless Steel | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 Crs 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Qalabyada Feeraska ah iyo kuwa aan birta ahayn ee loogu talagalay shubista Maalgelinta, Geedi socodka shubista Dhuxista:

- • Birta cawlan: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Birta Ductile ama Birta Nodular: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Birta Kaarboon: AISI 1020 - AISI 1060, C30, C40, C45.

- • Biraha birta ah: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...iwm marka la codsado.

- • Birta aan lahayn: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 iyo kuwa kale ee darajada birta ah.

- Naxaasta, Naxaasta Cas, Bronze ama biraha kale ee ku salaysan Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- Qalabka kale sida shuruudahaaga gaarka ah ama sida waafaqsan ASTM, SAE, AISI, ACI, DIN, EN, ISO, iyo heerarka GB

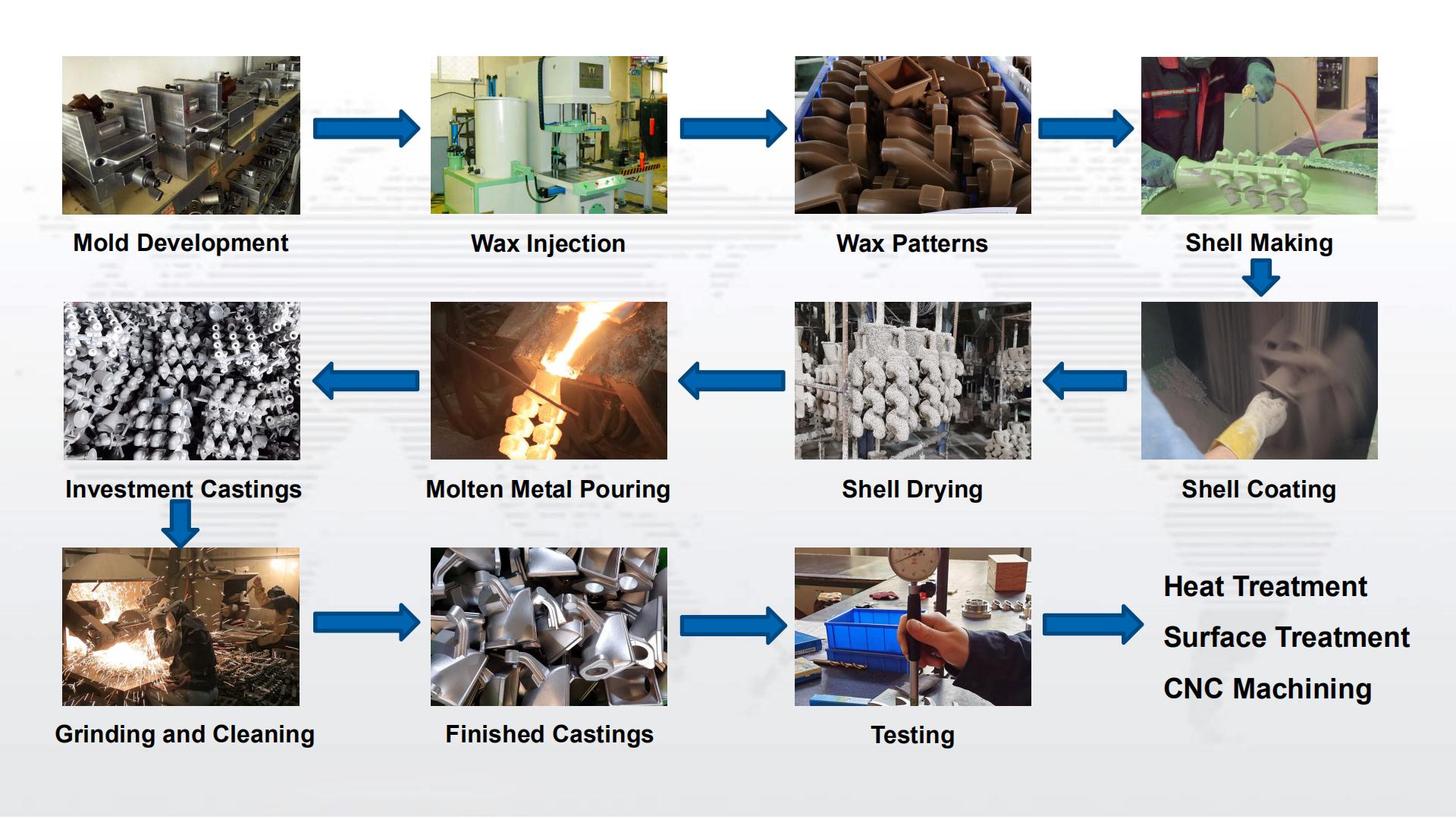

Tillaabooyinka ku lug leh habka ama shubista dhunka waa:

- • Samee qaab dhux ama nuqul

- • Daadi qaabka dhuka

- • Maalgeli qaabka dhuka

- • Ka takhalus qaabka dhuka adiga oo gubaya (gudaha foornada ama biyaha kulul) si aad u abuurto caaryar.

- • Xooga birta dhalaalaysa ku shub caaryada

- • Qaboojinta iyo adkaynta

- • Ka saar sprue ka tuurista

- • Dhamays oo turxaan bixi tuurista maalgelinta ee dhammaatay

Daawaynta Kulaylka ee AISI 316 Dheemooyinka Birta Aan-Aamaha ahayn:

Kuleylka ilaa 1900°F (1040°C) ugu yaraan, haysashada wakhti ku filan, dami biyo ama si degdeg ah u qabooji si kale. AISI 316 waxay la mid tahay CF8M/F316 iyo Heerka Shiinaha 0Cr17Ni12Mo2. AISI 314 waa molybdenum sidday wax ka beddelka AISI 304 daawaha waana kabka u dhigma la sameeyay CF8M birta aan lahayn. Joogitaanka molybdenum waxay kordhisaa caabbinta guud ee daxalka iyo caabbinta u yeelashada chlorides. Daawaha waxaa loo isticmaalaa xaaladaha aashitada khafiifka ah iyo alkaline-ka iyo maaraynta asiidhyada liinta, oxalic iyo fosfooraska.