Birta aan-dhalatada lahayn ayaa leh ugu yaraan 10.5% ka kooban chromium, taas oo ka dhigaysa mid adkaysi u leh bay'adaha dareeraha wasakhaysan iyo oksaydhka. Aad bay u adkaysa daxalka waxayna xidhataa adkaysi, waxay bixisaa mashiin aad u fiican, waxayna caan ku tahay muuqaalkeeda bilicda. Tuubadaha maalgashiga ee birta-la'aanta ah waa "daxalka u adkaysta" marka lagu isticmaalo jawi dareere ah iyo uumiga ka hooseeya 1200°F (650°C) iyo "kuleelka u adkaysta" marka loo isticmaalo in ka sarreeya heerkulkan.

Heerka u dhigma ee birta aan lahayn | |||||||

| Qaybaha | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic iyo Ferritic Stainless Steel | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 Crs 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Codsiyada Qaybaha Kaabista iyo Mashiinka Gaarka ah:

1. Qaybaha Baabuurta: Saxanka Biriiga, Isku Xidhka Usha, Axle Wadida, Shaft Drive, Gacanta Kontoroolka, Guryaha Gearbox, Daboolka Gearbox, Daboolka Xadhkaha, Guryaynta Xadhkaha, Taayirrada, Guryaha shaandhaynta, Hoyga Wadajirka ee CV, Quful Quful.

2. Qaybaha Gawaadhida: Gacmaha Rocker, Gearbox Gudbinta, Axles Drive, Gear Housing, Gear Cover, Jiidashada Indhaha, Connect Usha, Matoorka Daboolka, Daboolka Matoorka, Wadajirka Bolt, Qaadista Korontada, Crankshaft, Camshaft, Saliida digsiga.

3. Qaybaha Haydarooliga: Dhululubo Haydarooliga, Bamka Haydarooliga, Guriyeynta Gerotor, Vane, Bushing, Haanta Haydarooliga, Madaxa Dabaqaha Haydarooliga, Bracket Hydraulic Sylinder Bracket.

4. Mashiinada Beeraha iyo Qaybaha Cagafyada: Guryaha Gear, Daboolka Gear, Isku Xidhka Usha, Usha Torque, Matoorka Matoorka, Daboolka Matoorka, Guriyeynta Bamka Saliida, Bracket, Hanger, Hook, Bracket.

5. Tareenada tareenada iyo Baabuurta Xamuulka: Guryaynta Shock Absorber, Daboolka Nuugista Shock, Guryaha Gear Qabyo ah, Daboolka Qalabka Qabyada ah, Wedge iyo Cone, Taayirrada, Nidaamyada Bireega, Gacan-qaadayaasha, Hagaha.

6. Qaybaha Mashiinada Dhismaha: Gear, Kursiga Xambaarsan, Bambada Gear, Guryaha Gearbox, Daboolka Gearbox, Flange, Bushing, Sylinder Boom, Bracket Support, Haanta Haydarooliga, Ilkaha Baaldiga, Baaldi.

7. Qaybaha Qalabka Saadka: Taayirrada, Caster, Bracket, Sylinder Hydraulic, Forklift Spare Parts, Keydka Quful.

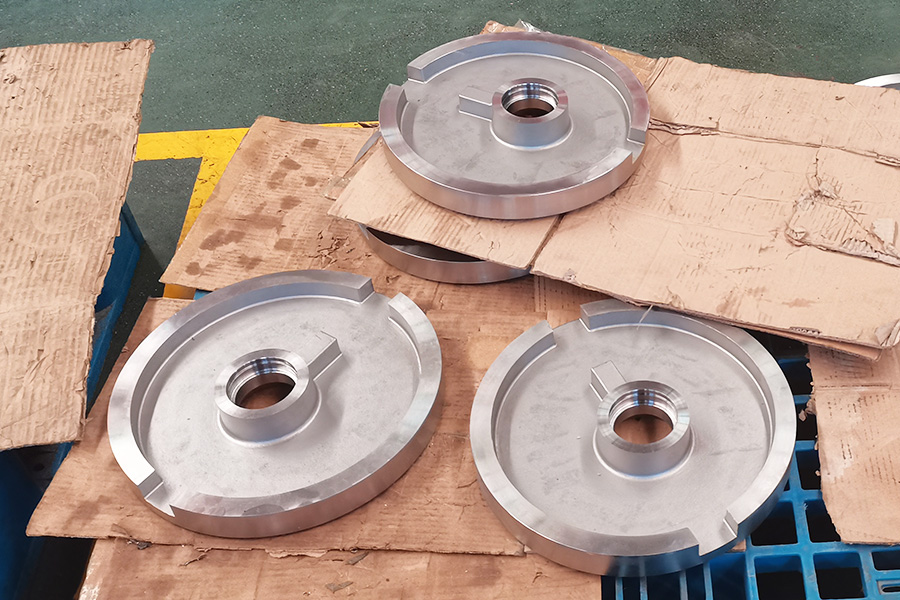

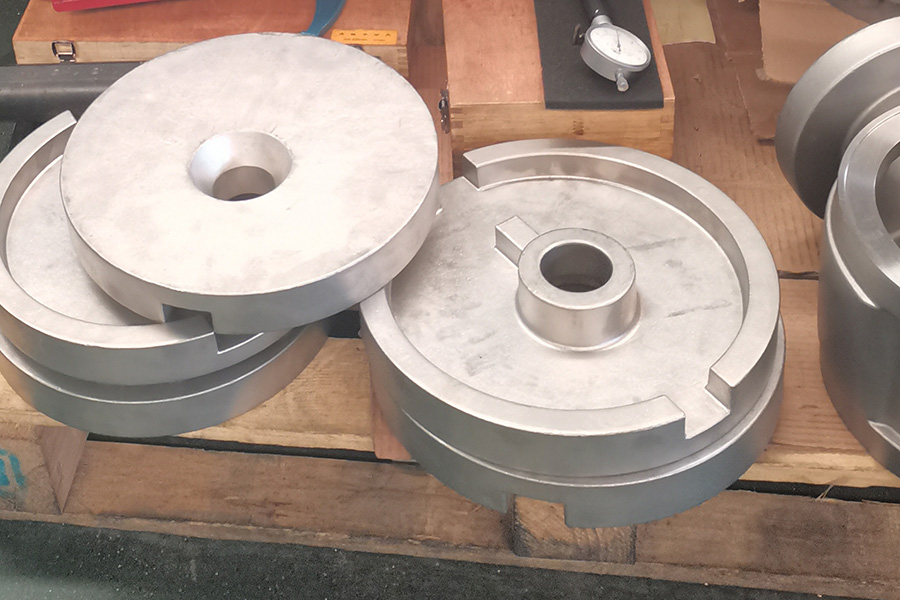

8. Qaybaha Valve and Pump: Valve Body (Gury), Balanbaalis Valve Disc, Ball Valve Housing, Flange, Connector, Camlock, Impeller Open, Impeller Close, Housing Pump (Jidhka), Daboolka Bamka.

Daawaynta Kulaylka ee AISI 316 Dheemooyinka Birta Aan-Aamaha ahayn:

Kuleylka ilaa 1900°F (1040°C) ugu yaraan, haysashada wakhti ku filan, dami biyo ama si degdeg ah u qabooji si kale. AISI 316 waxay la mid tahay CF8M/F316 iyo Heerka Shiinaha 0Cr17Ni12Mo2. AISI 314 waa molybdenum sidday wax ka beddelka AISI 304 daawaha waana kabka u dhigma la sameeyay CF8M birta aan lahayn. Joogitaanka molybdenum waxay kordhisaa caabbinta guud ee daxalka iyo caabbinta u yeelashada chlorides. Daawaha waxaa loo isticmaalaa xaaladaha aashitada khafiifka ah iyo alkaline-ka iyo maaraynta asiidhyada liinta, oxalic iyo fosfooraska.