CNC Machining Warshada

Mashiinka saxda ah waa habka loo gooyo qaybaha birta si ay ugu habboonaadaan codsiyada iyo hawlaha isticmaalaha dhamaadka. Inta badan habka mashiinada casriga ah waxaa fulisa Koombuyuutar Tiro-koobeedka, CNC, kaas oo kombuyuutarrada loo isticmaalo in lagu xakameeyo dhaqdhaqaaqa iyo shaqada mishiinnada, xashiishka, iyo mishiinnada kale ee wax lagu gooyo. Habkan wax-soo-saarka saxda ah, oo sidoo kale loo yaqaan mashiinnada CNC, ayaa door muhiim ah ka ciyaara warshadaha wax soo saarka casriga ah, gaar ahaan qaybo ka mid ah mashiinnada saxnaanta sare.

Codsiyada qaarkood, kaliyatuuridama been abuurka iyada oo aan makiinadu gaadhin dulqaadkii la rabay iyo shuruudaha dusha sare. Si kastaba ha ahaatee, xaalada inteeda badan, mishiinada ayaa loo baahan yahay si ay ula jaanqaadaan tafatirka gaarka ah ee macaamilka iyo in la hubiyo inqaybaha biraha dhammeeyeywaxay si habboon ula shaqayn kartaa qaybaha kale. Xitaa loogu talagalayqaybo shubista maalgashiga, kuwaas oo leh heer sare oo aad uga wanaagsan iyo heerka dulqaadka marka loo eego habka kale ee samaynta biraha, wali waxay u baahan yihiin hannaan farsamo oo dheeri ah.

Si loo hubiyo tayada sare iyo saxda ah ee la dhammeeyeyqaybaha mashiinada, barnaamijyada kombuyuutarku waa muhiim. Naqshadeynta Kaalmada Kombiyuutarka, oo loo yaqaan CAD si gaaban, iyo Wax-soo-saarka Kombiyuutarka Caawinta, oo loo yaqaan CAM, ayaa labadaba loo isticmaalaa sidii barnaamijyo si ay u bixiyaan tilmaamo faahfaahsan oo ku saabsan tallaabo kasta oo habka saxda ah ee farsamaynta. Barnaamijyada sida SolidWorks, ProE iyo UG waxay abuuraan moodallo 3D aad u faahfaahsan.

Waad ku mahadsan tahay mashiinnada CNC ee horumarsan iyo xarumaha mashiinnada dhidibka 4 ee labada nooc ee siman iyo kuwa toosan, RMC waxay ku takhasustay soo saarista qaybaha mashiinnada caadooyinka OEM ee leh xarunta mashiinka, mashiinnada CNC iyo aaladaha kale ee gaarka ah sida sawirada macaamiisha leh shuruudaha dulqaad adag iyo qallafsanaanta dusha sare. Tuubitaanka biraha birta ah iyo kuwa aan birta ahayn ayaa lagu farsameeyaa annagawarshada mashiinada, taas oo naga caawin karta inaan helno faa'iido weyn oo lagu xakameynayo kharashyada iyo tayada.

Habka Mashiinka CNC

Xarunta Mashiinka Tooska ah

Waxa aan ku gaari karno CNC Machining

| Xarumaha | Tirada | Baaxadda cabbirka | Awood Sannadeedka | Saxnaanta |

| Xarunta Mashiinka CNC ee Toosan (VMC) | 48 qaybood | 1500mm × 1000mm × 800mm | 6000 ton/sannad ama 300000 xabo sanadkii | ±0.005 |

| Horizontal CNC Machining Center (VMC) | 12 qaybood | 1200mm × 800mm × 600mm | 2000 ton/sannad ama 100000 xabo sanadkii | ±0.005 |

| Mashiinka CNC | 60 qaybood | Heerarka ugu sarreeya. φ600mm | 5000 ton/sannad ama 600000 xabo sanadkii |

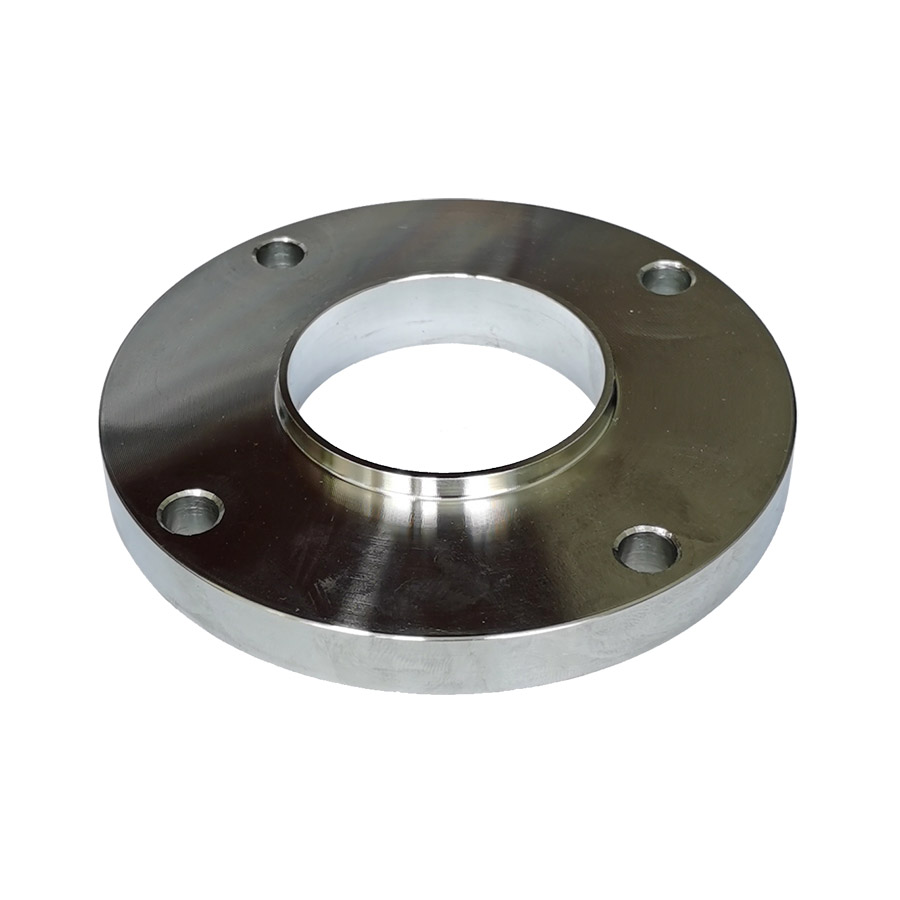

Qaybaha Mashiinka ee Hydraulics

Noocyada Birta & Alloys-ka ee lagu Makiinado Aqoon-is-weydaarsiga Mashiinka

• Birta Cas ee Cawlan

• Birta Ductile Cast

• Birta Kaarboon ee ka samaysan birta kaarboon yar, birta kaarboon dhexdhexaad ah iyo birta kaarboonka sare.

• Alloys birta laga bilaabo darajooyinka caadiga ah ilaa darajooyinka gaarka ah haddii la codsado.

• Aluminium, Zinc iyo alwaaxdooda

• Naxaas iyo Copper

• Birta Aan Lahayn, Duplex Steel Stainless

• Xidho birta u adkaysata, birta daxalka u adkaysata, birta u adkaysata kulaylka.

• Qalabka birta iyo Aluminium Profiles

• Aloy Forgings

Machining sax ah

Waa maxay hababka Machining ee aan samayn karno

Nidaamyada mashiinnada ee laga heli karo warshadda mashiinnada ee RMC CNC waa Turing, Facing, Boring, Milling, Drilling, Planning, Qaabeynta, Goojinta, Shiididda Wajiga, Shilinka Silindrical, Honing, Hobbing Gear, Dul dhigid, Lapping, Tapping...iwm.

- Honing

Habkani waxa uu isticmaalaa dhexroor dalool honing u dhexeeya 0.8 mm ilaa 100 mm oo qoto dheer ilaa 280 mm. Dulqaadka tooska ah waa 0.001 mm, wareega 0.0005 mm, iyo toosnaanta 0.0005 mm. Dhammaystirka dusha sare waa Ra 0.05 μm. Mashiinnada hoing ee toosan iyo kuwa toosan ayaa la isticmaalaa waxaana ku jira hal-spindle, mataano-spindle, iyo lix-spindle.

- jeestay

Tani waa habka loo gooyo hal dhibic oo gooyo adag ah. Nidaamkeena qallafsanaantu waxay mashiin karaan qaybo adag oo ka sarreeya 58 HRC ka dib daaweynta kulaylka, dhexroorka ugu badan ee 26 mm, dhererka leexashada ilaa 100 mm, dulqaadka cabbirka 0.005 mm, iyo qallafsanaanta Ra0.2μm.

- Shiida OD iyo aqoonsiga

Habkani waxa uu noo suurto gelinayaa in aan mashiinada ulaha leh dhexroor leh 750 mm, dhererka gudahood 1000 mm, wareega of 0.0004 mm, iyo cylindricity of 0.001 mm. Godadka gudaha waxay u dhexeeyaan 3 mm ilaa 100 mm.

- Deburting

Awoodaha furfurista ee RMC waxaa ka mid ah farsamaynta kiimikaad kiimikaad, habka tamarta kulaylka, iyo mishiinada qulqulka qulqulka. Kuwaas waxaa loo isticmaalaa hawo-mareenada, baabuurta, iyo hawada hawada oo leh godadka is-goysyada iyo godad gudaha ah oo adag si loo buuxiyo shuruudaha deminta adag.

- OD Shiidad aan Xarun lahayn

Tan waxaa loo isticmaalaa ulaha leh dhexroor leh 200 mm, dhererka 400 mm, dhexroor dulqaadashada 0.001 mm, cylindricity ilaa 0.0005 mm. Waxay diyaar u tahay quudinta iyo quudinta labadaba.

Horizontal Machining Center

Aqoon-is-weydaarsiga Mashiinnada CNC

Qalabka Sida Wanaagsan Loo Soo Agaasimay Ee Aan Ku Tiirsannahay Mashiinka Saxda Ah Ee CNC

Aqoon-is-weydaarsiga Mashiinnada CNC

Habka Mashiinka Saxda ah

Mashiinka CNC

Warshada Mashiinka

Xarunta Mashiinka Tooska ah

Horizontal Machining Center

Horizontal Machining Center

Qodista CNC

Workshop Machining

Adeegga Mashiinka ee CNC

Adeegga Mashiinnada Saxda ah

Xarunta Machining

Codsiyada Qaybaha Mashiinka ee CNC

Alaabadayada waxaa loo isticmaalaa guud ahaanwarshadahasida baabuurta, hydraulics, baabuurta xamuulka ah ee tareenada, xamuulka culus, qalabka saadka, tuubooyinka iyo bamka, saliidda iyo gaaska, iyo qalabka beeraha.

| • Tareennada tareenada | • Qalabka Saadka |

| • Gawaarida Xamuulka qaada | • Qalabka Beeraha |

| • Baabuur | • Haydarooliga |

| • Qalabka Dhismaha | • Nidaamyada Matoorka |

Alaabta Birta ah ee Mashiinka Saxda ah ee CNC

In ka badan CNC Machining

Sida adeeg bixiye hal joogsi ah iyo alaab-qeybiye dhammaystiranciid tuurid, shubista maalgashiga, foornada iyo mashiinada, waxaan sidoo kale bixinnaaadeegyadaee daaweynta kulaylka, daaweynta dusha oo leh kalsooni iyo dabacsanaan. Injineeradayadu waxay indhahooda ku hayaan habka wax soo saarka laga bilaabo naqshadaynta naqshadaynta alaabta la dhammeeyey, iyo sidoo kale jawaab celinta macaamiisha. Macaamiishu waxay nagu tiirsan yihiin naqshadaynta iyo taageerada injineernimada, agabka iyo taageerada wax-soo-saarka ee khuseeya guryaha iyo waxyaabaha gaarka ah. Waxaan leenahay gudaha-guriga awoodaha wax-ku-samaynta degdega ah iyo shaybaadhka guriga dhexdiisa, NDT, alxanka, iyo daawaynta kulaylka.

Sidaa darteed, waxyaabaha aan sameyn karno waa kuwo dhameystiran oo hal joogsi ah:

- Adeegyada:Naqshadeynta Qaabka, Soo jeedinta Qiimaha Hooseysa, Qalabaynta iyo Waxsoosaarka Qaabka, Muunadaha, Waxsoosaarka Tirada Badan, Saadka, Adeegga Kadib.

- Samaynta iyo Samaynta: Maalgelinta Maalgelinta, Qaadista Ciidda, Qaadista Dhimashada Cuf-jiidadka, Cadaadiska Sare ee Dhimista,Dhalinta Shell, Been abuurista, Mashiinada Saxda ah iyo Warshadaha Biraha.

- Daaweynta kulaylka:Deminta, Xanaajinta, Caadiyan, Kariimaynta, Carburization, Nitrotion

- Daaweynta dusha sare:Anodizing, Zinc-plating, Polising, GeoMet, Zintek....iwm

- Adeegga Imtixaanka:Halabuurka Kiimikada, Guryaha Makaanikada, Baadhitaanka Galitaanka Dhallaanka ama Magnetic (FPI, MPI), Raajooyinka, Baadhitaanka Ultrasonic

Si aad wax badan uga barato sida aanu uga caawin karno samayntaada iyo farsamaynta baahiyahaaga ama ka doodo fursadaha, kaliya xor u noqola xidhiidh kooxdayada injineernimadamaanta.

Qaybaha Mashiinnada Birta Ductile