China OEM caado daawaynta birta alloy byhabka shubista maalgashiga dhunka lumay. Birta kaarboon, birta daawaha hoose, iyo shubida birta qalabka ayaa loo isticmaalaa dhowrcodsiyada warshadahaiyomarsho habaysan. Darajooyinkooda tirada badan, birta iyo alwaaxdooda ayaa lagu daweyn karaa kulayl si loo hagaajiyo wax-soo-saarkeeda iyo xooggeeda; iyo, ku hagaaji adkaanta ama ductility baahida codsiga injineerka ama qalabka farsamada ee la doonayo.

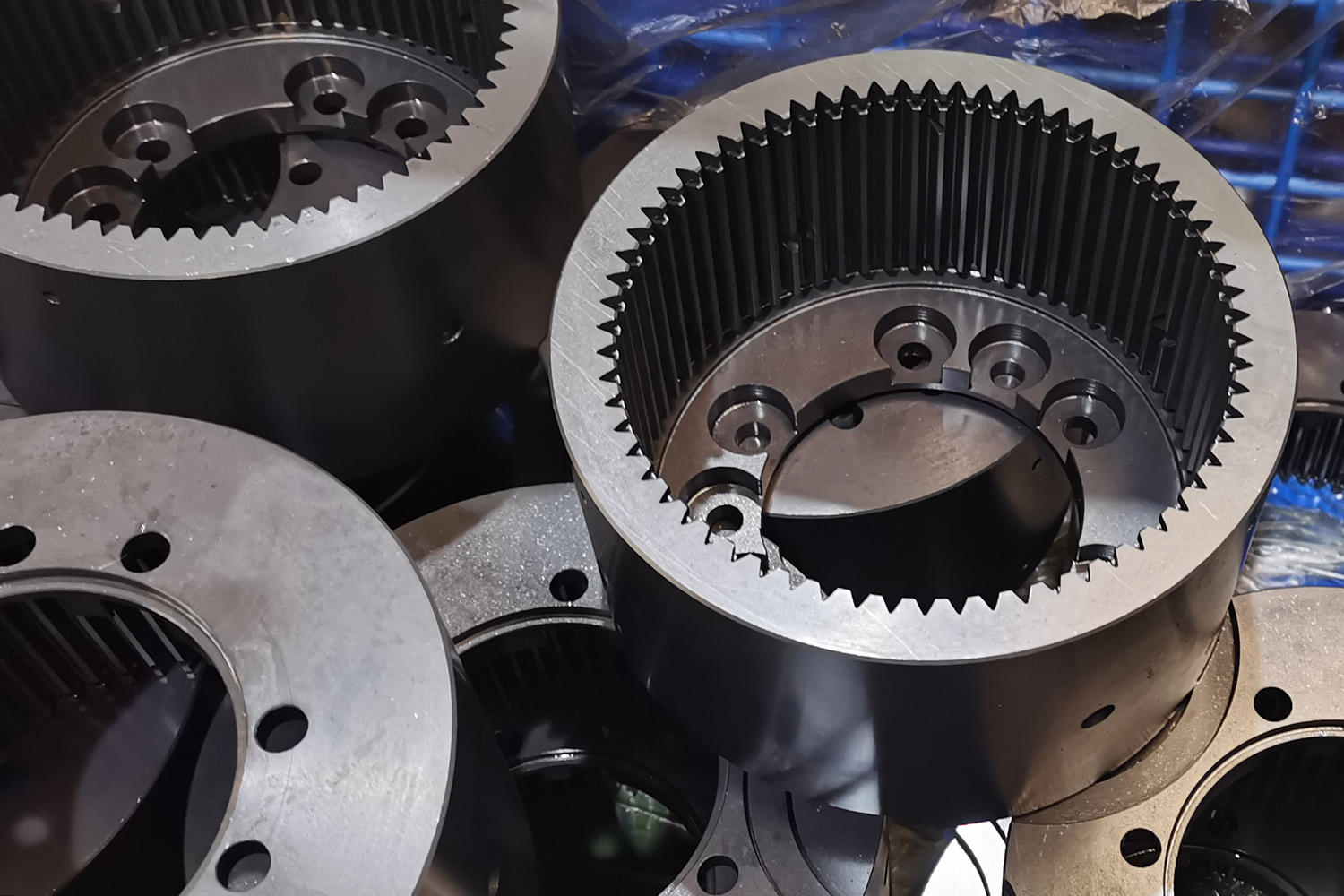

Dharka maalgashiga birta daawaynta u adkaysta waa qaybaha shubista ee ay soo saartay habka shubista maalgashiga dhuka ee lumay ee ka samaysan birta daawaha u adkaysta. Goobta RMC Foundry, hababka shubista ciidda ugu weyn ee aan u isticmaali karno birta daawaha u adkeysaneysa xirashada waa tuurista ciid cagaaran, shubista ciid dahaarka leh, shubista caaryada ciid aan duban, tuurista xumbo tuurista, shubista faakuumka iyo shubista maalgashiga. Daaweynta kulaylka, daaweynta dusha sare iyo mashiinka CNC ayaa sidoo kale laga heli karaa warshadeena sida sawiradaada iyo shuruudahaaga.

Waxaa ka mid ah noocyada kala duwan ee daawaynta wax shubidda, birta kabka ee xidhashada u adkaysata waa bir daawaha ah oo aad loo isticmaalo. Kabka u adkaysta xidhashada inta badan waxa ay wanaajisaa caabbinta xidhashada birta iyada oo ku daraysa waxyaabo kala duwan oo ah walxo alloying ah, sida manganese, chromium, carbon, iwm., daawaha. Isla mar ahaantaana, caabbinta xirashada ee dhejisyada birta u adkaysta waxay sidoo kale ku xiran tahay habka daaweynta kulaylka ee loo isticmaalo aasaaska iyo qaab dhismeedka shubista.

Marka loo eego sifooyinka xirashada ee kala duwan, xirashada dhejinta birta waxaa loo qaybin karaa xirmo xoqan, xirashada koollada, xirashada daalka, xirashada daxalka iyo xirashada xanaaqa. Tuubadaha birta u adkaysta ayaa inta badan loo isticmaalaa goobaha warshadaha leh xaalado shaqo oo adag iyo shuruudaha waxqabadka farsamada sare, sida macdanta, birta, dhismaha, tamarta, kiimikooyinka petrochemical, ilaalinta biyaha, beeraha iyo warshadaha gaadiidka. Tuubbooyinka birta u adkaysta ayaa inta badan loo adeegsadaa xaaladaha ciribtirka leh ee leh culays saamayn gaar ah leh, sida qalabka wax lagu shiido, kuwa qodaya, burburiyaha, cagafyada, iwm.

| Darajo u dhiganta ee birta dahaadhka ah ee loo yaqaan 'Cast Alloy Steel' oo laga helay suuqyo kala duwan | |||||||||

| KOOXAHA | AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Birta Alloy Low | 9255 | 1.0904 | 55 Si 7 | 250 A 53 | 2090 | 55 S 7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mn 5 | 150 M 36 | 2120 | 40 M 5 | 36Mn5 | SMn 438 (H) | - | |

| 1330 | 1.1170 | 28 Mn 6 | 150 M 28 | - | 20 M 5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Cr 6 | 534 A 99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220 (H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Nooca 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A 16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Cr 4 | 530 A 32 | - | 32 C 4 | 35Cr4 | SCr430 (H) | 34Cr4 (KB) | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Cr 4 | 530 A 40 | 2245 | 42 C 4 TS | F.1207 | SCR 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Cr 3 | 527 A 60 | 2253 | 55C 3 | - | SUP 9 (A) | 55Cr3 | |

| 4130 | 1.7218 | 25CrMo 4 | 1717CDS 110 | 2225 | 25 CD4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4 (KB) | |

| 4135 (4137) | 1.7220 | 35CrMo 4 | 708 A 37 | 2234 | 35 CD4 | 34CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42CrMo 4 | SCM 440 | 41CrMo 4 | |

| 4140 | 1.7225 | 42CrMo 4 | 708 M 40 | 2244 | 40 CD4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42CrMo 4 | 708 M 40 | 2244 | 42 CD4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CrV 4 | 735 A 50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Birta Alloy Dhexdhexaad | W1 | 1.1545 | C105W1 | BW1A | 1880kii | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CrV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Qalabka iyo Biraha Alloy High | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 292 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Birta Xoog-Xoogga Sare | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

AwoodahaAasaaska Maalgelinta Maalgashiga:

• Cabirka ugu badan: 1,000 mm × 800 mm × 500 mm

• Qiyaasta Miisaanka: 0.5 kg - 100 kg

• Awood Sannadeedka: 2,000 oo tan

• Qalabka dammaanadda ee Dhismaha Shell: Silica Sol, Muraayadaha Biyaha iyo isku-darkooda.

Dulqaadyada: Codsiga.

Faa'iidooyinkaQaybaha Kaabista Maalgashiga:

- Dhammaystir dusha sare oo heer sare ah oo siman

- Dulqaad adag oo cabbir ah.

- qaabab isku dhafan oo qalafsan oo leh dabacsanaan naqshadeed

- Awoodda lagu tuuro gidaarada khafiifka ah, sidaas awgeed waa qayb ka fudfudud

- Xulasho ballaadhan oo ah biraha la shubay iyo alloys (ferrous iyo non-ferrous)

- Qabyo looma baahna naqshadaynta caaryada.

- Iska yaree baahida mashiinada labaad.

- Qashinka alaabta hoose.

| Qalabka loogu talagalayMaalgelinta MaalgelintaGeedi socodka at RMC Foundry | |||

| Qaybta | Heerka Shiinaha | Heerka US | Heerka Jarmalka |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic ahama | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404.8. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Roobab Adkeynaysa Birta Aan Lahayn | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Qalabka Birta | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Birta u adkaysata kulaylka | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy-saldhigga Nickle | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Daawaha Copper | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-saldhig Alloy | UMC50, 670, Fasalka 31 | 2.4778 | |

| Dulqaadyada MAALGASHIGA | |||

| Inches | millimitir | ||

| Cabirka | Dulqaad | Cabirka | Dulqaad |

| Ilaa 0.500 | ±.004" | Ilaa 12.0 | ± 0.10mm |

| 0.500 ilaa 1,000” | ±.006" | 12.0 ilaa 25.0 | ± 0.15mm |

| 1.000 ilaa 1.500” | ±.008" | 25.0 ilaa 37.0 | ± 0.20mm |

| 1.500 ilaa 2,000” | ±.010" | 37.0 ilaa 50.0 | ± 0.25mm |

| 2.000 ilaa 2.500” | ±.012" | 50.0 ilaa 62.0 | ± 0.30mm |

| 2.500 ilaa 3.500” | ±.014" | 62.0 ilaa 87.0 | ± 0.35mm |

| 3.500 ilaa 5,000” | ±.017" | 87.0 ilaa 125.0 | ± 0.40mm |

| 5.000 ilaa 7.500” | ±.020" | 125.0 ilaa 190.0 | ± 0.50mm |

| 7.500 ilaa 10,000" | ±.022" | 190.0 ilaa 250.0 | ± 0.57mm |

| 10.000 ilaa 12.500" | ±.025" | 250.0 ilaa 312.0 | ± 0.60mm |

| 12.500 ilaa 15.000 | ±.028" | 312.0 ilaa 375.0 | ± 0.70mm |